We have been devoted to designing, developing and manufacturing pressure equipment for 10 years. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system. Our main products are all construction equipment ,such as color steel roofing sheet roll forming machines, C&Z purline machine, steel roof tile roll forming machines, floor deck forming machines, EPS sandwich panel roll forming machine, highway guardrail forming machine, shearing machine, bending machine, slitting machine. Our products are welcomed by domestic and overseas customers,such as India,Mozambique,Angola,Nigeria,Russia, Albania,France and so on. With strong technical power, we adhere to the principle of "acquire confidence from quality, based on honesty, keep innovation, win-win" and sincerely provide technique guidance, installation, debugging and processing services.

4. Our service

4.1.Payment Term: 40% paid by T/T as down payment, the rest 60% after inspection by buyer in seller’s factory while before delivery. After finished production, we will inspect the machine and inform the buyer, the buyer send person to inspect goods, then payoff the whole payment before shipping.

4.2.Delivery Time: We guarantees the equipment will be ready for shipment within 30 working days after receipt of deposit .

4.3.After sale Service: We could send technician to your country to install machine if you need. The buyer need to pay for extra cost, including: visa, round trip tickets, accommodation, salary of USD 100~120 per day.

4.4.Warranty: 12 months

During the warranty, the replaceable parts are free, but the buyers need to pay for the shipping . We will also provide you instruction manual to show you how to operate the machines.

5. FAQ (about our roll forming machine)

1)Q: What is the Warranty Machine ?

A: For our roll forming machine , we have 1 year warranty. If any quality problems in this period , we will not take on the shipping cost and replacement,we will provide some effective consultation to help solve problems.

2) Q: How do your machines compare with other big companies in this market?

A:Technology, quality and price are our trump card which let us serviced in the intense business competition. Use the newest technology to provide good quality machine with low price to our customer.

3)Q: How does your factory do regarding quality control?

A: Quality is first. We always attach great importance to quality control from the beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

5) Q: Will you deliver the right goods as ordered? How can I trust you?

A: Yes, we will. The core of our company culture is honesty and credit. We are ALIBABA’s gold supplier and we also support the “trade assurance”, our assurance amount is 24,000 USD now. If you check with ALIBABA, you will see that we have never got any complaint from our customers.

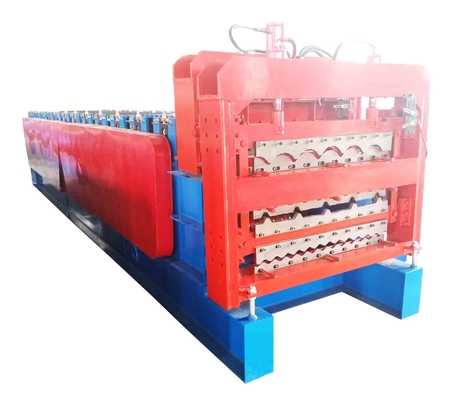

6.Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!