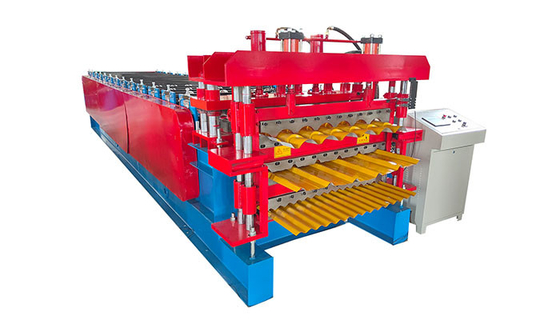

IBR Corrugated Metal Steel Glazed Tile Roofing Sheet Three Layer Roll Forming Machine

1. Three layer roll forming machine for steel tile making

---- To design and make the best roll forming machine, we took EUROPEAN quality standard;

---- Choose the best material and components, and adopting our 17+ years experience;

---- We achieves that the machine capacity is double of the competitors;

---- The machine working speed can be 60m/min;

---- Very easy to install and operate the roll forming machine.

2. Three layer roll forming machine for steel tile making parameters

| No. |

Item |

Specification |

| 1 |

Can Formed Material |

GI,AI |

| 2 |

Equipment operation |

Automatic |

| 3 |

Voltage |

380V 60Hz 3Phase or as your requirement |

| 4 |

Thickness of sheet (mm) |

0.3-0.7mm |

| 5 |

Material width(mm) |

As your requirement |

| 6 |

Cover Width of the sheet after formed |

as your drawing |

| 7 |

The size of the roll forming machine |

5500mmx1200mmx1400mm |

| 8 |

Speed |

12-15m/min |

| 9 |

Diameter of shaft |

40mm |

| 10 |

Weight of the Machine |

2200-2500KGS |

| 11 |

Material of rollers |

Cr12 steel quenched and chromed |

| 12 |

Motor brand |

Siemens or Guomao |

| 13 |

PLC |

Siemens or Delta or Mitsubushi |

| 14 |

Total power (kw) |

8kw |

| 15 |

Power of hydraulic system |

4kw |

| 16 |

Power of main molding core |

4kw |

| 17 |

Transmission |

Chain with gears |

| Machine Components |

| No. |

Name |

QTY |

| 1 |

Manual uncoiler |

1 set |

| 2 |

Feeding and leveling device |

1 set |

| 3 |

Roll forming system |

1 set |

| 4 |

Hydraulic punching and cutting |

1 set |

| 5 |

Product support frame |

1 set |

| 6 |

PLC Control System |

1 set |

3. roll forming machine company profiles

Botou Shitong Cold Roll Forming Machinery Manufacturing Co.,Ltd. is a professional manufacturer and exporter that are concerned with the design, development and manufactur of cold roll forming machines. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

We can also supply stud/ track/truss/furring frame roll forming machine, rolling shutter machine, door frame machine, high frequency tube welded forming machine, gutter machine, downpipe machine, floor deck machine and etc. Sticking to the principle of“Quality is our culture”. We can design according to our customers' requirements and we will do our best to meet your needs.

4. Our promise

We treat all customers as friend ,before purchasing ,we guide our customer to choose suit machine .after purchase,we supply effective after-sale service .We still try our best to let all customers satisfied not only our machine quality but also our service .

5. FAQ (about our roll forming machine)

A:- What is your payment term?

- 30% of the total payment should be paid as deposit ,the balanced should be paid after check the finished photos and videos well ,we supply test report.

B:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

C:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

D:- What is the after- sale service?

- 24 months from time of loading by seller quality guarantee, life guarantee repair.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

Within quality guarantee period, except for failures caused by human error, repair parts will be provided for free. After the

quality guarantee period, only charge the production cost of the spare parts.Free technical supporting and maintenance consulting in lifetime.

E:-Can you accept OEM?

- We can accept OEM

6.Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!