Product Description:

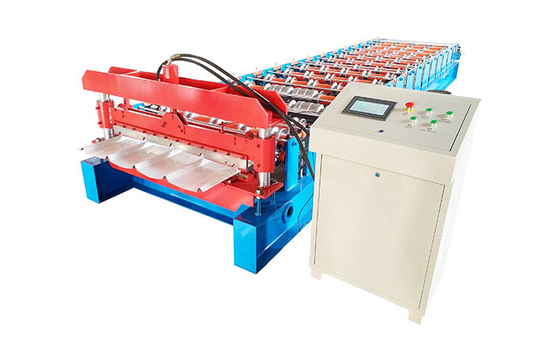

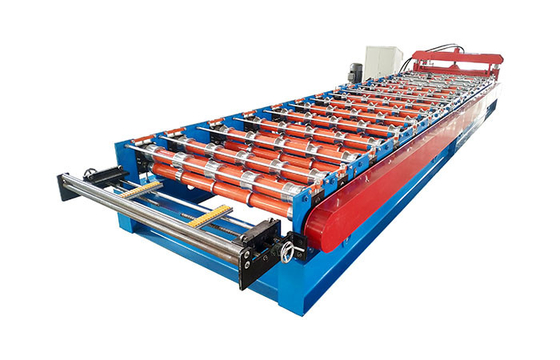

The Sheet Metal Roll Forming Machines are essential equipment for the metal rolling process, designed to efficiently and precisely shape sheets of metal into various forms. With advanced controls provided by the E21S system, these machines offer superior performance and accuracy in metal forming operations.

Key features of the Sheet Metal Roll Forming Machines include the use of high-quality roll material made of Gcr15 steel with quenching. This ensures durability and longevity, allowing the machines to withstand the rigors of continuous use in industrial settings. The diameter of the shaft, ranging from 70mm to 80mm, contributes to the stability and precision of the rolling process, resulting in consistent and high-quality output.

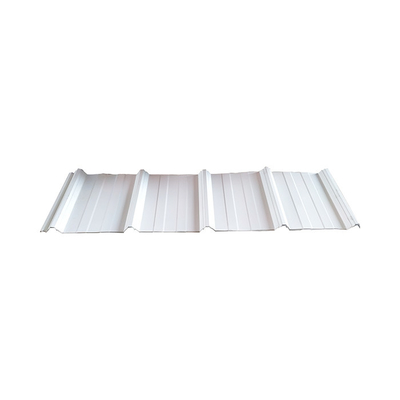

Equipped with cutters made of Cr12 heat treatment material, the Sheet Metal Roll Forming Machines are capable of producing a wide range of products. From 100 to 250 types of sheet metal forms can be created with ease, making these machines versatile and suitable for various applications in industries such as construction, automotive, and manufacturing.

Whether you are producing roofing sheets, wall panels, or other sheet metal components, the Sheet Metal Roll Forming Machines offer the flexibility and efficiency needed to meet your production requirements. The precise control provided by the E21S system ensures that each piece is formed accurately according to your specifications, resulting in consistent quality and dimensional accuracy.

With a focus on performance, durability, and versatility, the Sheet Metal Roll Forming Machines are the ideal choice for businesses looking to streamline their metal forming processes and increase productivity. The use of high-quality materials in construction, such as Gcr15 steel and Cr12 heat treatment material, guarantees reliable operation and long-term performance, minimizing downtime and maintenance costs.

Investing in Sheet Metal Roll Forming Machines can help your business stay competitive in the market by improving efficiency, reducing material waste, and enhancing product quality. Whether you are a small workshop or a large-scale manufacturing facility, these machines can make a significant difference in your metal forming operations, providing consistent results and quick turnaround times.

Experience the benefits of advanced technology and precision engineering with the Sheet Metal Roll Forming Machines. Upgrade your metal forming processes today and take your production capabilities to the next level with these reliable and versatile machines.

Applications:

The SHITONG Roll Forming Machine, model IBR, is a high-quality sheet metal roll forming machine designed for various metal rolling processes. Originating from China and certified with CE, this machine offers precision and efficiency in forming metal sheets according to specific requirements.

With a minimum order quantity of 1 set and pricing dependent on models, the SHITONG Roll Forming Machine is suitable for a wide range of applications. It is ideal for manufacturing metal roofing sheets, wall panels, and other architectural components that require precise bending and shaping.

The packaging details of this machine include being covered with plastic film to ensure protection during transportation. The delivery time for the machine is estimated to be 40-50 days, with payment terms accepted via T/T.

With a supply ability of 20-30 sets per month, the SHITONG Roll Forming Machine is equipped with 13-15 stations rollers and a shaft diameter of 70-80mm. The cutting tolerance of the machine is ±2mm, allowing for accurate and consistent results in metal sheet forming.

The forming speed of the machine ranges from 10 to 20 meters per minute, making it a productive and efficient tool for various metal bending applications. As a type of tile forming machine, it is versatile and can be used in different scenarios requiring sheet metal roll forming.

Customization:

Product Customization Services for Sheet Metal Roll Forming Machines:

Brand Name: SHITONG Roll Forming Machine

Model Number: IBR

Place of Origin: China

Certification: CE

Minimum Order Quantity: 1 SET

Price: Depends On Models

Packaging Details: Covered With Plastic Film

Delivery Time: 40-50 Days

Payment Terms: By T/T

Supply Ability: 20-30 Sets Per Month

Type: Tile Forming Machine

Dimension: 7000*1500*1500mm

Hydraulic Motor Power: 3-7.5kW

Cutting Tolerance: ±2mm

Forming Speed: 10-20 Meters Per Minute

Keywords: Metal Rolling Process, Roll Forming Equipment, Sheet Metal Roll Forming Machine

Support and Services:

Our company offers comprehensive Product Technical Support and Services for our Sheet Metal Roll Forming Machines. Our team of experts is dedicated to providing assistance with installation, training, troubleshooting, and maintenance of the machines.

We provide detailed product manuals, instructional videos, and online resources to help our customers utilize the roll forming machines effectively. Additionally, our technical support team is available to address any inquiries or issues that may arise during the operation of the machines.

Our services also include regular maintenance programs to ensure optimal performance and longevity of the Sheet Metal Roll Forming Machines. Customers can rely on our expertise to enhance productivity and efficiency in their operations.

FAQ:

Q: What is the brand name of the sheet metal roll forming machine?

A: The brand name of the machine is SHITONG Roll Forming Machine.

Q: What is the model number of the sheet metal roll forming machine?

A: The model number of the machine is IBR.

Q: Where is the sheet metal roll forming machine manufactured?

A: The machine is manufactured in China.

Q: What is the certification of the sheet metal roll forming machine?

A: The machine is CE certified.

Q: What are the packaging details for the sheet metal roll forming machine?

A: The machine is covered with plastic film for packaging.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!