Product Description:

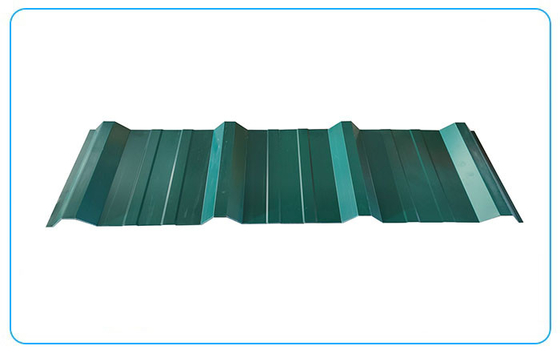

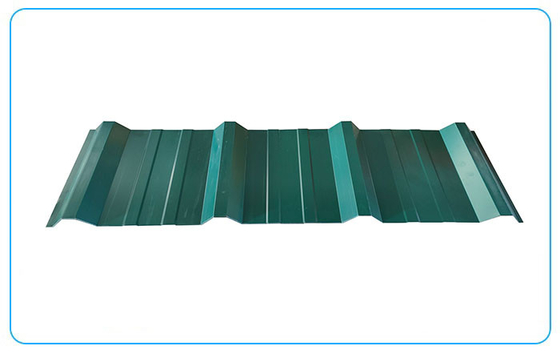

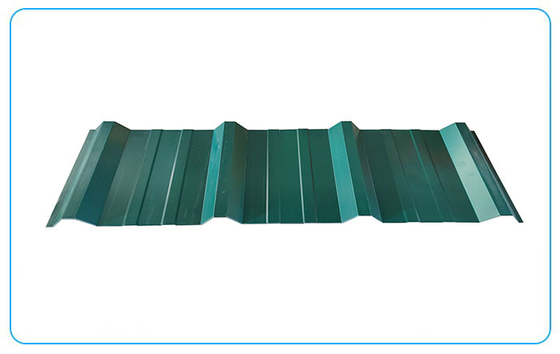

A Sheet Metal Roll Forming Machine is an essential piece of equipment for various industries involved in metalworking and construction. Specifically designed for shaping and bending metal sheets, these machines play a crucial role in creating a wide range of products such as roofing sheets, panels, and other metal components.

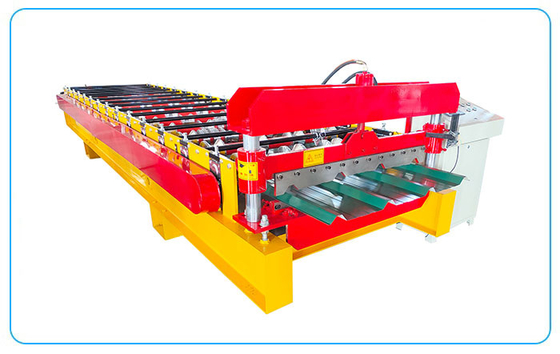

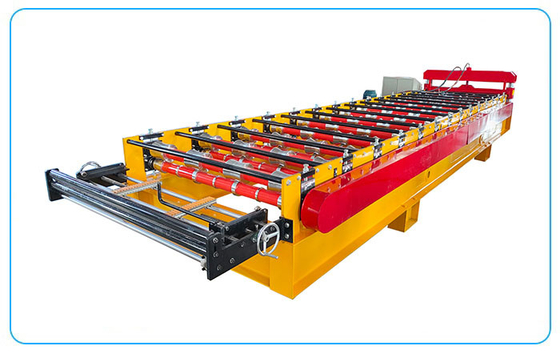

One exemplary product in this category is the Sheet Metal Roll Forming Machine with the following key attributes:

-

Diameter Of Shaft:

70-80mm

-

Suitable Material:

Colored Galvanized Steel Sheet

-

Cutter Material:

Cr12 Heat Treatment

-

Type:

Tile Forming Machine

-

Dimension:

7000*1500*1500mm

The Sheet Rolling Machine is equipped with a shaft diameter ranging from 70mm to 80mm, allowing for precise and efficient metal bending operations. Its compatibility with colored galvanized steel sheets makes it ideal for creating durable and visually appealing metal components.

The Cutter Material of Cr12 Heat Treatment ensures the durability and sharpness of the cutting tool, enhancing the machine's overall performance and longevity. This feature enables the machine to accurately cut and shape metal sheets with precision, resulting in high-quality finished products.

As a Tile Forming Machine, this Sheet Metal Roll Forming Machine is specifically designed for producing various types of tiles and panels used in roofing and cladding applications. Its versatility and efficiency make it a valuable asset for manufacturers and construction companies looking to streamline their production processes.

With dimensions of 7000*1500*1500mm, this Metal Bend Machine offers a compact yet sturdy construction, making it suitable for different workshop settings. Its ergonomic design and user-friendly controls ensure ease of operation, allowing operators to work efficiently and safely.

In conclusion, the Sheet Metal Roll Forming Machine with the specified attributes is a reliable and high-performance tool for shaping and bending metal sheets with precision and accuracy. Whether used in the production of roofing sheets, panels, or other metal components, this machine offers a versatile and efficient solution for various metalworking applications.

Applications:

SHITONG Roll Forming Machine's Sheet Metal Roll Forming Machines, model IBR, are versatile equipment designed for various product application occasions and scenarios. These machines are manufactured in China and come with CE certification, ensuring high-quality standards.

The Sheet Metal Roll Forming Machines are ideal for metal bend machine applications, where precise bending and shaping of sheet metal are required. They are widely used in industries such as construction, automotive, manufacturing, and more. With a minimum order quantity of 1 set, these machines offer flexibility for small-scale and large-scale production needs.

These sheet metal processors are equipped with rollers featuring 13-15 stations, allowing for efficient and accurate sheet rolling processes. The cutter material, Cr12 heat treatment, ensures durability and precision in cutting operations, with a cutting tolerance of ±2mm.

SHITONG Roll Forming Machine's Sheet Metal Roll Forming Machines are powered by a servo motor drive motor, providing reliable and smooth operation. The roll material, Gcr15 steel with quenching, enhances the longevity and performance of the machines, making them suitable for continuous use.

When it comes to packaging and delivery, the machines are covered with plastic film for protection during transportation. The delivery time ranges from 40-50 days, ensuring timely arrival of the equipment. Payment terms are by T/T, offering convenience for transactions.

With a supply ability of 20-30 sets per month, these sheet metal roll forming machines are readily available to meet the demands of various industries. The price depends on the models chosen, catering to different budget requirements.

Customization:

Product Customization Services for the Metal Bend Machine - Sheet Metal Roll Forming Machine

Brand Name: SHITONG Roll Forming Machine

Model Number: IBR

Place Of Origin: China

Certification: CE

Minimum Order Quantity: 1 SET

Price: Depends On Models

Packaging Details: Covered With Plastic Film

Delivery Time: 40-50 Days

Payment Terms: By T/T

Supply Ability: 20-30 Sets Per Month

Dimension: 7000*1500*1500mm

Roll Material: Gcr15 Steel With Quenching

Hydraulic Motor Power: 3-7.5kW

Diameter Of Shaft: 70-80mm

Forming Speed: 10-20 Meters Per Minute

Support and Services:

Our product technical support and services for Sheet Metal Roll Forming Machines are designed to provide comprehensive assistance to our customers. Our team of experts is available to help with installation, troubleshooting, and maintenance of the machines.

We offer training programs to ensure that customers are able to operate the machines efficiently and maximize their performance. Additionally, our technical support team is available to address any questions or concerns that may arise during the use of our products.

Our goal is to provide top-notch technical support and services to ensure the smooth operation of Sheet Metal Roll Forming Machines for our customers.

FAQ:

Q: What is the brand name of the sheet metal roll forming machines?

A: The brand name is SHITONG Roll Forming Machine.

Q: What is the model number of the sheet metal roll forming machines?

A: The model number is IBR.

Q: Where are the sheet metal roll forming machines manufactured?

A: The machines are manufactured in China.

Q: What certification do the sheet metal roll forming machines have?

A: The machines have CE certification.

Q: What is the minimum order quantity for the sheet metal roll forming machines?

A: The minimum order quantity is 1 set.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!