Product Description:

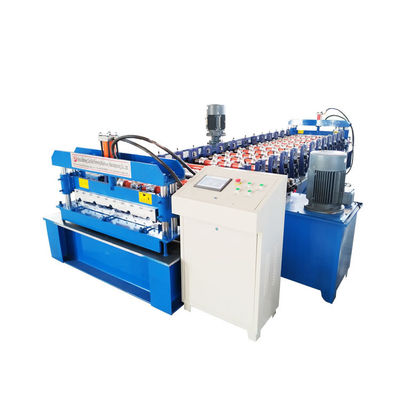

One of the key features of the Sheet Metal Roll Forming Machines is the hydraulic motor power, ranging from 3 to 7.5kW. This ensures that the machines have the necessary strength and force to effectively shape the metal sheets according to the desired specifications. Whether you are working on thin or thick metal sheets, these machines can handle the job with precision and accuracy.

The roll material used in these machines is Gcr15 steel with quenching, known for its durability and resistance to wear and tear. This high-quality material ensures that the rolls have a long lifespan and can maintain their shape and performance even after prolonged use. With the Gcr15 steel rolls, you can trust that your sheet metal rolling process will be smooth and consistent.

Equipped with E21S controls, the Sheet Metal Roll Forming Machines offer user-friendly operation and precise control over the rolling process. The intuitive interface allows operators to easily adjust the settings and parameters to achieve the desired outcome. Whether you are a seasoned professional or a beginner in metalworking, these machines make the process straightforward and efficient.

With a product range covering all types from 100 to 250, these roll forming machines are suitable for a wide range of applications and sheet metal thicknesses. From roofing panels to automotive components, these machines can handle various types of metal sheets with ease. The versatility of the product range makes it a valuable addition to any metalworking workshop or manufacturing facility.

In conclusion, the Sheet Metal Roll Forming Machines are a reliable and efficient solution for all your metal rolling needs. With precise dimensions, powerful hydraulic motor, durable roll material, user-friendly controls, and a versatile product range, these machines offer everything you need to streamline your metalworking processes. Invest in these roll forming machines and experience the benefits of enhanced productivity, accuracy, and quality in your sheet metal fabrication projects.

Applications:

The Sheet Metal Roll Forming Machines from SHITONG Roll Forming Machine are versatile equipment designed for various product application occasions and scenarios. These machines, under the model number IBR, are proudly manufactured in China and come with a CE certification, ensuring high quality and safety standards.

With a minimum order quantity of 1 set, the price of the machines depends on the specific models chosen. The packaging details include being covered with plastic film to protect the equipment during transportation. Customers can expect a delivery time of 40-50 days after placing their order, with payment terms typically being by T/T.

These Sheet Metal Roll Forming Machines have a supply ability of 20-30 sets per month, making them readily available for various industrial needs. The cutter material used is Cr12 Heat Treatment, ensuring durability and precision in the metal rolling process.

Equipped with a hydraulic motor power ranging from 3-7.5kW and a diameter of shaft between 70-80mm, these machines offer efficient and reliable performance. The roll material used is Gcr15 Steel with quenching, further enhancing the durability and quality of the metal rolling process.

These machines also offer ODM services, providing customization options to meet specific requirements. The Sheet Metal Roll Forming Machines are suitable for a wide range of applications, including but not limited to roofing, construction, and manufacturing industries.

Customization:

Product Customization Services for Sheet Metal Roll Forming Machines:

Brand Name:

SHITONG Roll Forming Machine

Model Number:

IBR

Place Of Origin:

China

Certification:

CE

Minimum Order Quantity:

1 SET

Price:

Depends On Models

Packaging Details:

Covered With Plastic Film

Delivery Time:

40-50 Days

Payment Terms:

By T/T

Supply Ability:

20-30 Sets Per Month

Hydraulic Motor Power:

3-7.5kW

Rollers:

13-15 Stations

Controls:

E21S

Roll Material:

Gcr15 Steel With Quenching

Machine Type:

IBR Machine With Curving

Support and Services:

Product Technical Support and Services for Sheet Metal Roll Forming Machines:

Our technical support team is available to assist you with any questions or issues you may have regarding the operation, maintenance, or troubleshooting of our sheet metal roll forming machines. Whether you need help with setup, calibration, or software updates, our experts are here to provide you with the support you need.

In addition to technical support, we also offer a range of services to help you get the most out of your machine. This includes training programs for operators and maintenance staff, as well as preventive maintenance services to keep your machine running smoothly. Our goal is to ensure that you have the tools and knowledge necessary to maximize the performance and lifespan of your sheet metal roll forming machine.

FAQ:

Q: What is the brand name of this product?

A: The brand name of this product is SHITONG Roll Forming Machine.

Q: What is the model number of this roll forming machine?

A: The model number of this machine is IBR.

Q: Where is this roll forming machine manufactured?

A: This machine is manufactured in China.

Q: What is the certification of this roll forming machine?

A: This machine is certified with CE.

Q: What are the packaging details for this product?

A: The machine is covered with plastic film for packaging.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!