Product Description:

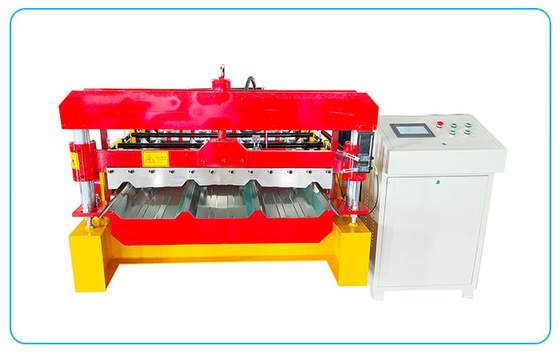

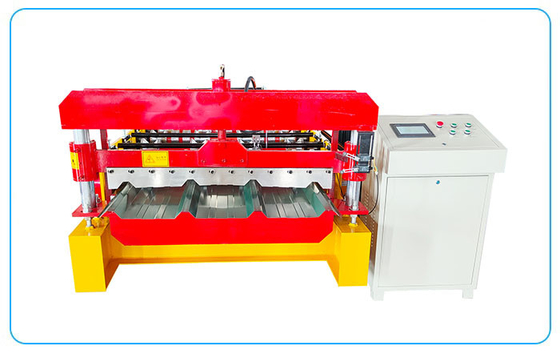

The Sheet Metal Roll Forming Machine is a versatile and efficient piece of equipment designed to streamline the process of shaping sheet metal. This machine is an essential tool for any metalworking operation that requires precision bending and forming of sheet metal.

One of the standout features of this Sheet Metal Roll Forming Machine is its advanced controls system. Equipped with the E21S control system, this machine offers unparalleled precision and ease of operation. The user-friendly interface allows operators to easily input parameters and control the entire forming process with precision.

With dimensions of 7000*1500*1500mm, this Sheet Rolling Machine is compact enough to fit into most workshops while still providing ample working space for various sheet metal forming projects. The sturdy construction ensures stability and durability, even during heavy-duty use.

When it comes to the quality of the rolls, this machine does not disappoint. The rolls are made of high-quality Gcr15 steel with quenching treatment, ensuring exceptional durability and resistance to wear. This means that the machine can maintain precise forming dimensions over a long period of time, resulting in high-quality finished products.

The Sheet Metal Roll Forming Machine is equipped with 13-15 stations, allowing for a wide range of forming possibilities. Whether you need simple bends or complex shapes, this machine can handle it all with ease. The rollers are precisely engineered to deliver consistent and accurate results every time.

Powering this machine is a robust hydraulic motor with a power range of 3-7.5kW. This motor provides ample power to drive the forming process efficiently, ensuring smooth and precise operation. With this power output, operators can confidently tackle a variety of sheet metal forming tasks with ease.

In conclusion, the Sheet Metal Roll Forming Machine is a reliable and efficient tool for any metalworking operation. Whether you are working on simple bends or intricate shapes, this machine delivers consistent and precise results every time. With its advanced controls, durable construction, high-quality rolls, and powerful hydraulic motor, this machine is a must-have for any workshop looking to streamline its sheet metal forming processes.

Applications:

Product Application Occasions and Scenarios for the SHITONG Roll Forming Machine IBR:

The Sheet Metal Roll Forming Machines from SHITONG are versatile and efficient tools designed for various applications in the sheet metal industry. With a brand name synonymous with quality and reliability, these machines are ideal for a wide range of product manufacturing needs. Here are some common scenarios where the SHITONG Roll Forming Machine IBR can be effectively utilized:

1. Roofing Industry: The IBR model is perfect for producing high-quality metal roofing sheets. Its precise metal bending capabilities ensure consistent and accurate profiles, making it a preferred choice for roofing material manufacturers.

2. Construction Sector: Sheet Metal Rollers are essential equipment for the construction industry. Whether it's for creating wall panels, gutters, or flashings, the SHITONG Roll Forming Machine offers the perfect solution for shaping colored galvanized steel sheets with ease.

3. Manufacturing Units: Metal bend machines play a crucial role in various manufacturing processes. The IBR model, with its CE certification and reliable performance, is well-suited for mass production environments where efficiency and precision are paramount.

4. Custom Fabrication Workshops: For businesses involved in custom metal fabrication, having a Sheet Metal Roller like the SHITONG IBR can streamline the production process. Its hydraulic motor power, servo drive motor, and cutting tolerance of ±2mm make it a valuable asset in creating bespoke metal components.

5. Industrial Workshops: The SHITONG Roll Forming Machine is designed to handle continuous operation, making it an ideal choice for industrial workshops with high production demands. Its sturdy construction, roll material of Gcr15 steel with quenching, and supply ability of 20-30 sets per month ensure long-term performance and reliability.

Overall, the SHITONG Roll Forming Machine IBR is a versatile and dependable tool for anyone working with sheet metal. Whether you need to create roofing panels, wall cladding, or custom metal components, this machine offers the precision, efficiency, and quality required for a wide range of applications.

Customization:

Product Customization Services for Metal Rolling Machine - Sheet Metal Roll Forming Machines:

Brand Name: SHITONG Roll Forming Machine

Model Number: IBR

Place Of Origin: China

Certification: CE

Minimum Order Quantity: 1 SET

Price: Depends On Models

Packaging Details: Covered With Plastic Film

Delivery Time: 40-50 Days

Payment Terms: By T/T

Supply Ability: 20-30 Sets Per Month

Type: Tile Forming Machine

ODM: Available

Roll Material: Gcr15 Steel With Quenching

Diameter Of Shaft: 70-80mm

Forming Speed: 10-20 Meters Per Minute

Support and Services:

Our Product Technical Support and Services for Sheet Metal Roll Forming Machines include:

- Troubleshooting assistance for machine operation and performance issues

- Guidance on machine setup, calibration, and maintenance

- Training programs for operators and maintenance personnel

- Software updates and technical documentation

- On-site support for complex technical issues

- Warranty services and repairs

FAQ:

Q: What is the brand name of the Sheet Metal Roll Forming Machines?

A:

The brand name is SHITONG Roll Forming Machine.

Q: What is the model number of the Sheet Metal Roll Forming Machines?

A:

The model number is IBR.

Q: Where are the Sheet Metal Roll Forming Machines manufactured?

A:

The machines are manufactured in China.

Q: What is the certification of the Sheet Metal Roll Forming Machines?

A:

The machines are CE certified.

Q: What is the minimum order quantity for the Sheet Metal Roll Forming Machines?

A:

The minimum order quantity is 1 set.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!