A. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also trainyour workers/technician face to face.

B. Without visiting, we will send you user manual and video to teach you to install and operate.

C. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

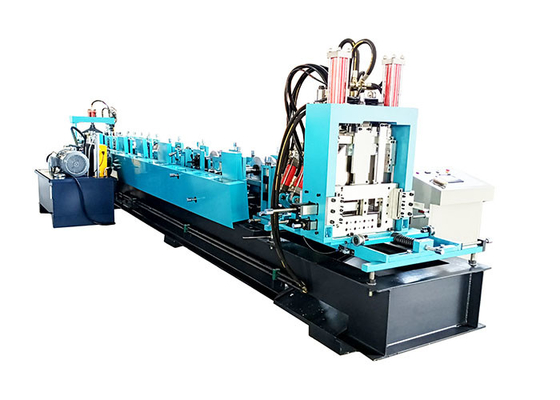

5. Our Machine Advantage

1. Good quality: We have a professional designer and experienced engineer team.And the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation:All machine cotrolling by PLC computer controlling systerm.

5. Elegant apperance:Protect the machine from rust and the painted colour can be customized

6. Reasonable price:We offer the best price in our industry.

package and Warranty:

- 1. Nude,with waterproof cloth and stow-wood.Imported computer control system packed with waterproof cloth and card board.

- 2. This producing line is maintained free of charge for 18 months.When the machine is used in China,we will install and debug the machine for free;if it is used at abroad,we will send the professional technician to debug.Buyers should take all the fees for technicians travelling abroad.

- 3. All the parts in the roll forming machine is free to maintain all the life,if in 18 months our company bear the cost for exchanged the broken part like the new parts cost and express cost,if more than 18 month,we also free to maintain the broken parts but for send the new parts,the buyer need bear the express cost.

- 4. When ship the roll forming machine,We will also send one set CD and specification(Chinese and English) to you with the machine,they can teach you how to operater the machines.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!