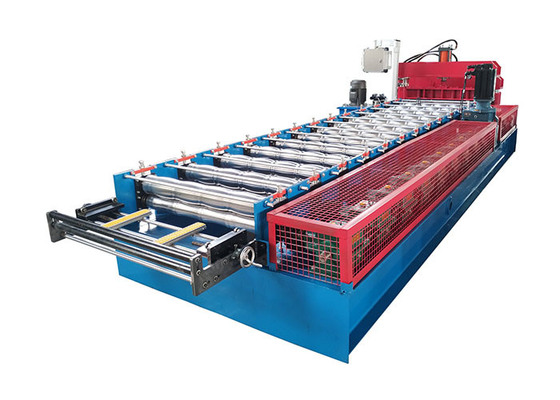

High Speed Aluminum Roll Forming Machines , Metal Roof Tile Rolling Machines With Hydraulic Power

1. Usage And Instroduction Of This Production Line

Tile roofing sheets are available in a wide range of materials displaying various structural properties. It should be noted that the load span characteristics are only to be used as a broad guideline as purlin spacing is also depend on other factors such as the prevailing winds in a certain area, snow during winter periods, the presence of dust and other particles in industrial areas, the type of structure that is being erected etc.. We therefore recommend that an engineer is consulted to determine the purlin spacing for a specific application.

2. Feature of the glazed tile roof machine

- The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connectors are screw which make the machine flexible and stronger.

- All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

- We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

- It is very easy to install the equipment and suitable for producing in the factory.

- Low noise with high efficienc

3. Specifications of the roll forming production line

| No. |

Automatic Used Metal Roof Panel Tile Roll Forming Machine |

| 1 |

Suitable material |

PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| 2 |

Thickness of coil sheet |

0.3-0.8mm |

| 3 |

Coil width |

1000mm |

| 4 |

Effective width |

828mm |

| 5 |

Material of main frame |

400H steel |

| 6 |

Diameter of Soild shaft |

70mm, high grade 45# steel |

| 7 |

Roller |

High grade 45# steel, quenched and tempered treatment,

hard chrome plated 0.05-0.07mm

|

| 8 |

Thickness of middle plate |

16mm, 45# steel plate |

| 9 |

Forming station |

11rows |

| 10 |

Drive type |

By chain(1.0 inch), link bearing model 6210 |

| 11 |

Power of main motor |

5.5 kw, servo motor删除表格 |

| 12 |

Sidewall connection bar |

25mm, zinc plated |

| 13 |

Forming speed |

About 12-18m/min |

| 14 |

Hydraulic pump station |

11 kw, 40# hydraulic oil |

| 15 |

PLC |

DELTA(TAIWAN)/Mitsubishi |

| 16 |

Material of razor blades |

Cr 12, quenching 58-62℃ |

| 17 |

Frequency converter |

It has the advantage of slowing down before cutting, to ensure

the length accuracy ±1mm, far better than industrial standard

±3mm.

|

| 18 |

Switch |

CHNT |

| 19 |

Frequency changer |

SAJ |

4. Our company service

Our company are professional product the roof roll forming machine manufacture , We manufacture and supply variants of cold roll forming machines in China, such as trapezoidal roofing sheet roll forming machine ,corrugated roofing roll forming machine ,glazed tile roll forming machine and double layer roofing sheet roll forming machine ,ridge cap roll forming machine and so on , our machine export all over the world like india.south africa.pakistan.Brazil .omen and so no , the color steel roof roll forming machine raw material thickness 0.3mm-0.8mm, we also can make other metal roofing sheet roll forming machine as your requirement ,meet your need ,our company aim :reputation first, customer first.

We have profuse designs with series quality grade, and expressly, our price is very competitive because we are manufactory, we are the source.Our first focus is quality improvement and customer's satisfaction,we have exported the products to Africa, South America, Russia, India, Pakistan,Southeast Asia etc. the custormers of domestic and foreign evaluate highly for our stable quality and cost effective.

5. Some machine pictures for your reference

6. FAQ

Q1. What's your payment terms and delivery time?

A1: 30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspect the machine well and before

delivery.

After we get down payment, we will arrange production. About 30-45 days for delivery.

Q2. Do you have after-sales support?

A2: Yes, we are happy to provide advice and we also have skilled technicians available across the world.

Q3. Do you sell only standard machines?

A3: No, most of our machines are built according to customers specifications, using top brand components.

Q4. What will you do if the machine is broken?

A4: We provide 24 months free warranty and free technical support for the whole life of any machine.If the broken parts can'trepair, we can send the new parts replace the broken parts freely, but you need pay the express cost by yourself. If it is beyond the warranty period, we can negotiate to solve the problem, and we supply the technical support for the whole life of the equipment.

Q5. Can you be responsible for transport?

A5: Yes, please tell me the destination port or address. we have rich experience in transporting.

Q6. How to visit your company?

A6: 1) Fly to Beijing airport, By high speed train From Beijing Nan to Cangzhou Xi (1 hour).

2) Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!