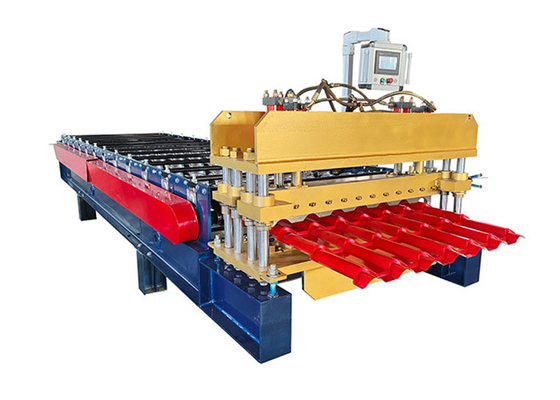

Colombia Type Glazed Tile Roll Forming Machine With Step Roofing Sheet Design

1. Brief of our company

Botou Shitong Cold Roll Forming Machinery Manufacturing Co.,Ltd. is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

"The quality first, The prestige first" is the service aim of our company, we wish to customize the best machines for customers. So all stuff from our company welcome anyone who are interested in our machines come to investigate and talk about cooperation.

2. Specifications of the roll forming production line

| Control System | PLC Inverter , Delta brand |

| Power Supply | 3Phase,380V,50Hz |

| Main Frame | 350 H-Beam |

| Main Power | 5.5kw |

| Pump Power | 7.5kw |

| Forming Speed | 4 - 5 m/min |

| Roll Station | 14 Stands |

| Roller Diameter | 70mm |

| Hydraulic Pressure | 10-12 MPa |

| Forming Size | 1200 mm raw material width |

| Feeding Thickness | 0.3-0.6mm |

| Feeding material | steel coil |

| Backboard Thickness | 16mm |

| Chain Size | 1 inch |

| Cutter material | Cr12 |

| Roller material | 45 # steel with hard chrome |

| Cr-Plating Size | 0.05mm |

| Overall Size | 7000×1500×1600mm |

| Total Weight | 4.5T |

3. Our advantage of the machine

1, this equipment using high level automatic control software, the realization of information management.

2, the automation control system USES high integration of network, the automation system performance is superior.

3, This machine also has the operation, maintenance, maintenance and debugging machinery, mold the advantages of easy replacement.

4, pressure plate, solemn elegant, beautiful novel, and smooth appearance, uniform corrugated, utilization rate is high, strength, producing a high degree of automation, low cost, durable.

4. Components of the roll forming machine

| Machine Components |

| No. | Name | QTY |

| 1 | Manual uncoiler | 1 set |

| 2 | Feeding and leveling device | 1 set |

| 3 | Roll forming system | 1 set |

| 4 | Hydraulic pressing and cutting | 1 set |

| 5 | Product support frame | 1 set |

| 6 | PLC Control System | 1 set |

5. FAQ

1). Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan for the machine.

2): How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

3).What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

4):How is this machine's service life?

A:In the normal maintenance,the service life at least 10 years.

6. Machine pictures for your reference

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!