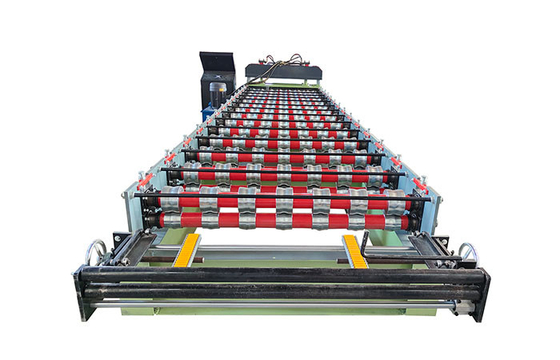

Color Steel Coil Metal Sheet Roof Glazed Tile Roll Forming Machine Effective Width 1100mm

1. Usage And Instroduction Of This Production Line

High quality glazed tile IBR sheet glazed tile roof press making machine roll forming machinery is for make the roof sheet for construction.This roof press making machine using for produce both glazed tile in up layer and trapezoid sheet in down layer.

As many different shapes roofing sheets,the roofing sheet shape customized.This is just for your reference of one set we sold before.

2. Metal roof glazed tile roll forming machine advantages and features:

For this roof press making machine, we have below advantage:

- We choose a innovative way that already solved the glazed tile press step distance problem.

That method can ensure the each finished glazed tile will in a same distance step and can be well overlap one by one together.

This can save you a lot of money and time for you about this problem.

- We are focus on machine detail design, will use many years experience to supplement the machine details and avoid some problems.

Will improve the machine service life.

Installation is quick: the light weight composite panels, installation and splicing can be arbitrarily cutting characteristics, determine its simple installation, can greatly improve efficiency, save construction period.

High strength: high strength steel for the substrate (tensile tensile strength 5600KG / CM) coupled with the most advanced design and roll forming, with excellent structural properties.

3. Specifications of the roll forming production line

| No. |

Item |

Specification |

| 1 |

Can Formed Material |

PPGI,GI,AI |

| 2 |

Equipment operation |

Automatic |

| 3 |

Voltage |

380V 60Hz 3Phase or as your requirement |

| 4 |

Thickness of sheet (mm) |

0.3-0.6mm |

| 5 |

Material width(mm) |

As your requirement |

| 6 |

Cover Width of the sheet after formed |

as your drawing |

| 7 |

The size of the roll forming machine |

7500mmx1600mmx1750mm |

| 8 |

Speed |

0-15m/min |

| 9 |

Diameter of shaft |

70mm |

| 10 |

Weight of the Machine |

8000-9500KGS |

| 11 |

Material of rollers |

C45 steel quenched and chromed |

| 12 |

Motor brand |

Siemens or Guomao |

| 13 |

PLC |

Siemens or Delta or Mitsubushi |

| 14 |

Total power (kw) |

9.5kw |

| 15 |

Power of hydraulic system |

5.5kw |

| 16 |

Power of main molding core |

4kw |

4. Our company service

SHITONG is a private enterprise with many years’ experience in this field. We have developed many new style Profile Forming Equipment, which enriches our products, makes our machinery more reasonable, artistic and practical. Therefore, we obtain the consistently high praise of new and regular customers.

1) Our engineers free of charge for customer training

roll forming machine

2) guide customers to operate and maintain equipment

roll forming machine

3) customers can ask engineers to client countries for machine installation and commissioning

4) Electrical parts of the machine we use PE film packaging, moisture-proof waterproofing

We have profuse designs with series quality grade, and expressly, our price is very competitive because we are manufactory, we are the source.Our first focus is quality improvement and customer's satisfaction,we have exported the products to Africa, South America, Russia, India, Pakistan,Southeast Asia etc. the custormers of domestic and foreign evaluate highly for our stable quality and cost effective.

5. Some machine pictures for your reference

6. FAQ

1:- What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

2:- Can you finish the machine during the delivery time?

- We will finish the machine in time according to determined lead time.

3:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

4:- Do you have any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

5:- Can you accept OEM?

- We can accept OEM.

6:- Any certification:

- Yes, we have CE TUV BV certification.

7. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team to work out the most suitable design and production plan for the machine.

8: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

9.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!