CNC Steel Door Profile Frame Roll Forming Making Machine Metal Garage Door Making Machinery

1. Steel door frame roll forming machine by customized

We can provide door frame equipment with accurate punching and beautiful molding to meet the customer's need for punching during the construction process,and solve the problem of the customer's appearance and surface appearance during use.And we can provide customized steel door frame equipment solutions used in the installation of interior doors in civil buildings.

2. Steel door frame roll forming machine by customized parameters

| (1)The general machine parameter |

| Suitable roll forming material |

Cold Rolling Mills |

| Thickness |

0.6-1.0mm |

| Frame design |

Wall-plate-frame-design /Strong-stand-frame-design |

| Roll stages |

16 stages |

| Material of forming roller |

45# Steel, CNC lathes, Hard Chrome Coated |

| Shafts Diameter |

Φ75mm |

| Main motor power |

5.5KW, frequency speed control |

| Max. Line speed of roll former |

15m/min (Higher speed is available, depends on the specification required by the buyer) |

| Hydraulic group power |

4 KW |

| Material of cutting blade |

Cr12, heat treatment |

| Electric Standard |

380V /50Hz/3PH or as the customer's requirements |

| Machine Dimensions |

8750mm×1380mm×1400mm |

| Major Color of Machine Painted |

RAL 5015 (Blue) or as per customer’s requirements |

| Machine Components |

| No. |

Name |

QTY |

| 1 |

Manual uncoiler |

1 set |

| 2 |

Feeding and leveling device |

1 set |

| 3 |

Roll forming system |

1 set |

| 4 |

Hydraulic punching and cutting |

1 set |

| 5 |

Product support frame |

1 set |

| 6 |

PLC Control System |

1 set |

3. After-sales service

In correct operation & maintaining, the machine is guaranteed for one year since leaving our factory excludes the electric elements.

Installation:

(1) If installation is needed, Liming (the seller) will dispatch technician to the buyer’s factory abroad to assist regulating the machine with charge free. The buyer should assist Liming to get the Chinese technician's visa and should pay for the roundtrip air ticket and the local accommodation.

(2) If installation is needed, the buyer shall make the following preparation before arrival of technicians.

a) Position the machine in the buyer’s factory.

b) Prepare necessary electric wiring.

c) Prepare material of trial running.

d) Provide labors for assistance and installation during installation.

e) If possible, One Chinese-speaking interpreter so that the communication between the buyer and seller’s technician will go smoothly.

4. FAQ

4.1. How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation of the machine.

4.2. What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

4.3. How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

4.4. How is your Payment Term?

A:T/T, Western Union

4.5. What’s your delivery time?

A:Normally it is about 45 days, but we will delivery as soon as possible

5. Company strength introduction

Our technical force is abundant. Production equipment is advanced, detection means is complete. We specialize in the professional production of various types of roll forming machines, and the development and production of fully automatic intelligent control roll forming machines of C-shaped steel and dust collector anode plates, and other equipment.

Our factory has highly qualified and experienced professionals and highly skilled construction workers to serve you. Our factory can design and produce various kinds of special-shaped cold-formed molding equipment for different needs of the users.

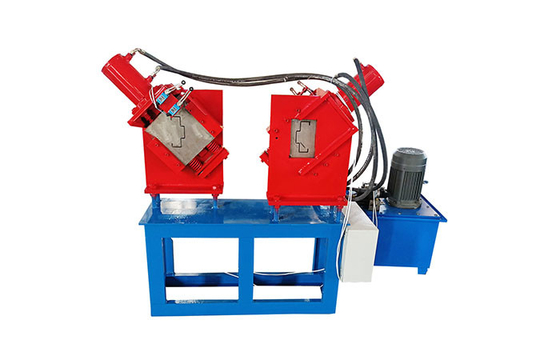

6. Roll forming machine pictures

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!