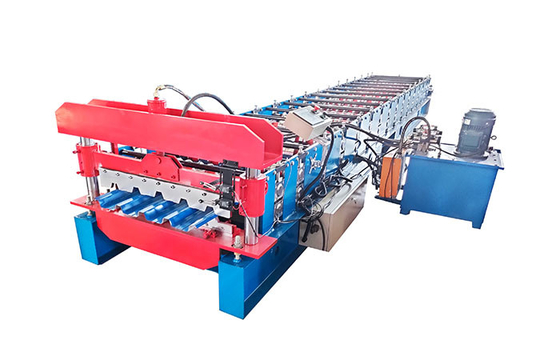

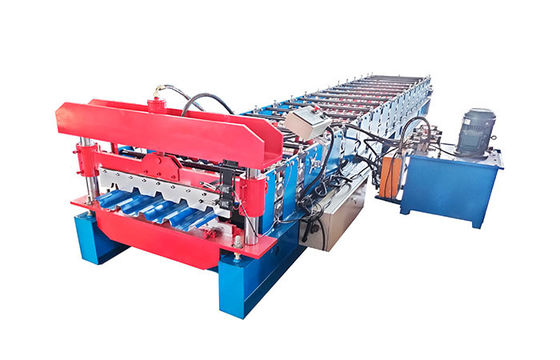

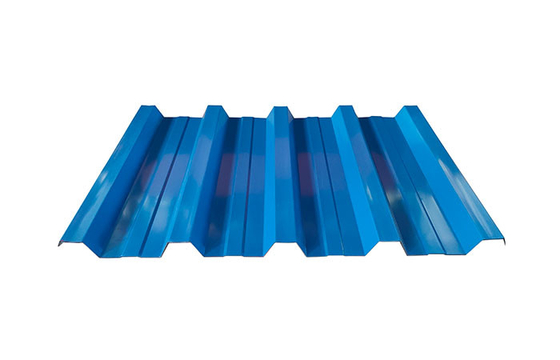

Steel Metal Roof Trapezoidal Sheet Iron Roofing Zinc Sheet Roll Forming Machine

1. Brief of our company

Our roll forming machine can be profile custom,and are lower cost,high efficiency,reliable working ,low energy consumption.we can do any type of equipment according to customer requirements.

This type of forming machine line includes various kinds of roof panel forming machines, wall panel forming machines, and lining plate forming machines , C Z purlin roll forming machines, guard rail roll forming machines, metal deck roll forming machines, guide rail roll forming machines etc. It has received 3 patents of utility model and is widely used in steel construction enclosure. We can provide roll forming equipment in various profile shapes and configurations to satisfy your specific requirements.

2. Specifications of the roll forming production line

| 1. |

Power

requirement

|

Type |

380v/3ph/50hz |

| |

|

Main Motor power |

3kw |

| |

|

Cutter power |

5.5kw with 2.2 kw servo motor |

| 2. |

Forming speed(m/min) |

40-45m/min max |

Not include the time of cutting |

| 3. |

Forming stations |

12stations |

|

| 5. |

Material of rollers |

CR12 |

|

| 6. |

Thickness of structure |

30mm |

|

| 7 |

Forming shaft diameter(mm) |

40 |

|

| 8 |

Drive |

Gear box |

|

| 9 |

Type of cutting |

Hydraulic cutting |

|

| 10. |

Control system |

PLC xinjie |

|

| 11. |

Install dimension(depend on the final design) |

4.8m×0.6m×1.2m |

Without panel length |

| 12. |

Total weight (Approx) |

2.3T |

Depend on final design |

| 13. |

Screen |

Text screen /touch screen |

|

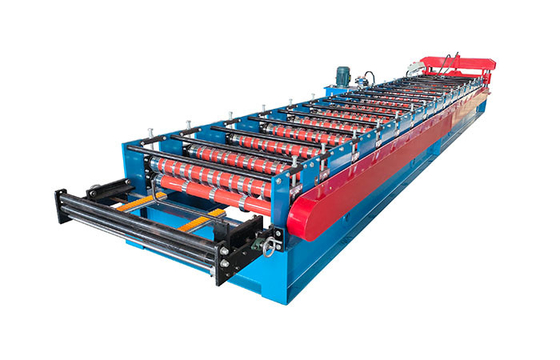

3. Features of the roll forming machine production line

a) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

b) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

d) It is very easy to install the equipment and suitable for producing in the factory.

e) Low noise with high efficiency

4. Components of the roll forming machine

| Machine Components |

| No. |

Name |

QTY |

| 1 |

Manual uncoiler |

1 set |

| 2 |

Feeding and leveling device |

1 set |

| 3 |

Roll forming system |

1 set |

| 4 |

Hydraulic pressing and cutting |

1 set |

| 5 |

Product support frame |

1 set |

| 6 |

PLC Control System |

1 set |

5. FAQ

1):How to maintenance?

A:If using frequently,best coating lubricant on the chain and two ends of the shaft every month, replace the hydraulic oil every 1-2 years.

2):What can you do if the machine broken?

A:Our machine's warranty period is 1 year,

if the broken parts can't repair,we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.

if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

3):Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

4):Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

6. Machine pictures for your reference

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!