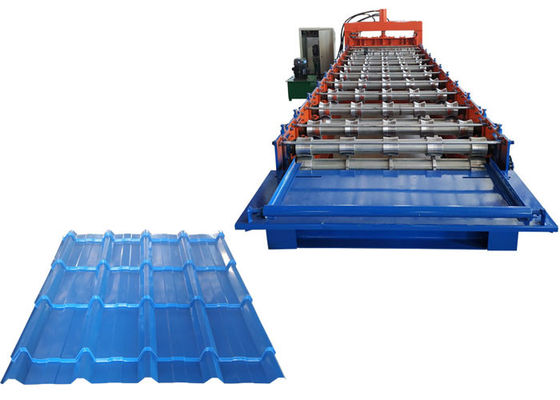

Color steel aluminum roofing iron sheet arc glazed tile roll forming machine building material machinery

1. Brief introduction of our machine

The machine production line includes: Manual uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting system, discharge table

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

2. Specifications of the roll forming production line

| 1. Suitable material |

Color steel sheet , galvanized steel sheet,aluminum sheet |

| 2. Installation Dimension (L*W*H): |

6.5m*1.5m*1.4m(depend on design) |

| 3. Main motor power |

About 3KW to 6KW with Cycloidal reducer |

| 4. Hydraulic station power |

About 3KW to 6KW |

| 5. Hydraulic oil pump |

CB-E 310 |

| 6. Thickness of material |

0.2mm~0.8mm |

| 7. Diameter of principal axis |

Φ70mm to Φ90mm |

| 8. Material expand width |

1000,1200,1250mm |

| 9. Electric tension |

380V 3phase 50HZ or as the customer's requirements |

| 10. Material of roller |

High grade 45# forged steel plated with hard chrome plating |

| 11. Controlling system |

PLC control canbinet |

| 12. Processing speed |

3-5m/min |

| 13. Processing precision within |

1.00mm (depend on design) |

| 14. Material of cutting blade |

Cr12 mould steel with quenched treatment |

| 15. Kind of drive |

0.6 inch chain link bearing model 6210 |

| 16. Roller station |

8-20 Rollers |

| 17. Roller material |

high grade 45#steel; Cr12 quenching |

| 18. Leak frame load-bearing |

4.6T |

3. Hydraulic Cutting device

It is controlled by gear wheel oil pump.

After filling the hydraulic oil into the hydraulic oil tank, the pumps drive the cutter machine to begin the cutting job.

The system includes: a set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. And two sets of electromagnetism valves.

Power of the oil pump motor: 4kw Hydraulic oil :46#

4. PLC Control System

It adopts industrial computer to control.

The target piece’s length is adjustable and digit of it can be adjusted.

Computed mode has two Modes: automatic one and manual one. The system is easy to operate and use.

5. Our company profile

BOTOU SHITONG COLD ROLL FORMING MACHINERY MANUFACTURING CO.,LTD.(hereinafter referred to as SHITONG) is founded in 2005 and specialized in designing, manufacturing, installation, debugging kinds of Metal Panel Roll Forming Machines. SHITONG is a private enterprise with many years’ experience in this field. We have developed many new style Profile Forming Equipment, which enriches our products, makes our machinery more reasonable, artistic and practical. Therefore, we obtain the consistently high praise of new and regular customers.

6. Some machine pictures for your reference

7. FAQ

1). If our country's voltage is different from yours, how to solve that?

The usual voltage is 380v,220v,415v. If yours are not one of them, we will design the electric motor to suit your voltage.

2). How to visit our company :

Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi(1 hour),then we can pick up you.

Fly to Shanghai Airport:By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5hours),then we can pick up you.

3). What can you do if the machine broken?

Our machine's warranty period is 1 year,

if the broken parts can't repair,we can free send the new parts replace the broken parts to you except the solenoid valve,the solenoid valve you must pay the express cost yourself.

if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!