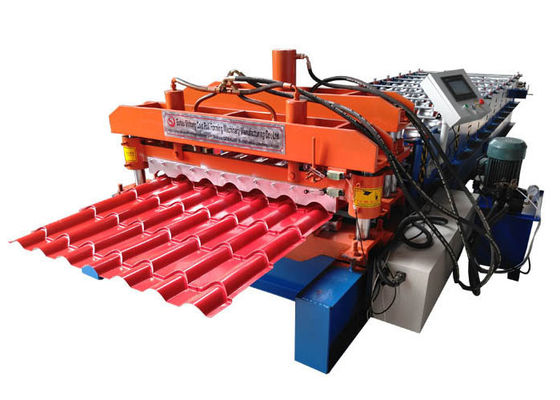

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Our advantage

1. We are a factory with nearly 20 years experiences on Roll Forming Machines;

2. We have our own research and development team with strong ability to solve all kinds of problems;

3. We have stable raw material suppliers to ensure the best quality and on time supplying with low cost;

4. We have more than 20 technicians that can go abroad for the after-sale service;

5. We have more than 100 kinds and models products for your choice, you can find the most kind of roll forming machines from us;

6. We have Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. advanced production equipments to ensure the quality of each part and the best appearance of our machines;

7. Our machines have reached the International Inspection Standards;

8. We have got the ISO9001:2008 Certificate and CE Certificate;

9. We are always waiting to serve you 7 days a week and 24 hours a day.

5. FAQ

Q1:What is the MOQ?

A:For roll forming machine,the MOQ is one set.

Q2:Could you design the machine for me?

A:Yes,we have professional team of engineers and are able to design and product roll forming machine as your requestment. Or if you have own drawings,we can design it as your drawings.

Q3:Are you trading company or factory?Can we visit your factory?

A:We have our own production line and factory.Warmly welcome to our factory. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q4: What's your after-sale service?

A: We'll provide engineer overseas service to help you install and debug the machine,in addition,free replacement of parts in one year warranty.

Q5: How is your Payment Term?

A:T/T,L/C ,Western Union

Q6: What’s your delivery time?

A:Normally it is about 45 days, but we will delivery as soon as possible

6. Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!