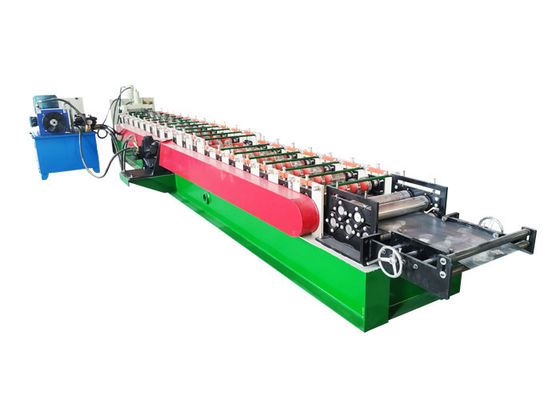

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Comapny advantage:

1. Low cost, light weight but high strength, short building period, and re-cycle use

2. Save material , no waste.

3. Easy operation, low maintenance cost

4. Infinite sizing(any size within machine range),help to save material

5. Optional Punch hole at any position of purlin web side and flange side

5. FAQ

1. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

2. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

3. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

4. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

5. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem. We can provide 2 years free quality assurance.

6. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

6. Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!