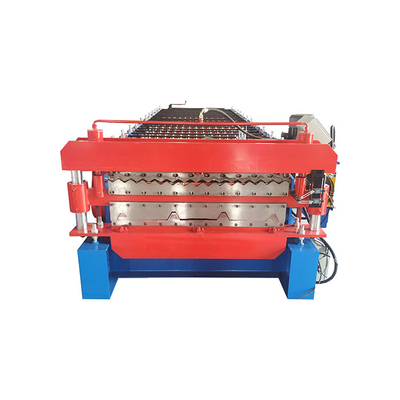

Metal Building Materials Roofing Sheet Making Machine Double Layer Roll Forming Machine

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Comapny advantage:

In Botou, we start the pressure roll forming machine export business from 2008.

As a manufacturer we are specialized in all kinds of roll forming machine, we are not machine supplier, we are a roll forming solution provider.

Provide best price,good quality and fast delivery.

5. FAQ

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce 2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

Q2. You don't show the product I need, can you manufacture it?

Our company's engineers have studied in well-known European cold bending companies and have great advantages in machine design and R&D and manufacturing.

Q3. How long can the machine be built?

Generally speaking, the machine takes about 40 days to complete, if you need a machine urgently, we can make it urgently, because I have a large number of spare parts.

Q4. Why are your prices higher than others?

Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q5. Do you have after-sales support?

Product quality is the ultimate, the biggest after-sales service is service, 26 years of production experience, to be a service company that you have the strength to guarantee

Q6. How to get a quotation?

Give me the dimension drawing and thickness, it is very important. 2. If you have requirements for production speed, power, voltage and brand, please explain in advance. 3. If you don't have your own outline drawing, we can recommend some models according to your local market standard.

Please feel free to contact us:

Contact person: Jessie Wang

Whatsapp/Wechat: +8613230728517

Email: jessie@shitongjixie.com

ADD:No. 1 Road, Economic Development Zone, botou, Hebei, China

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!