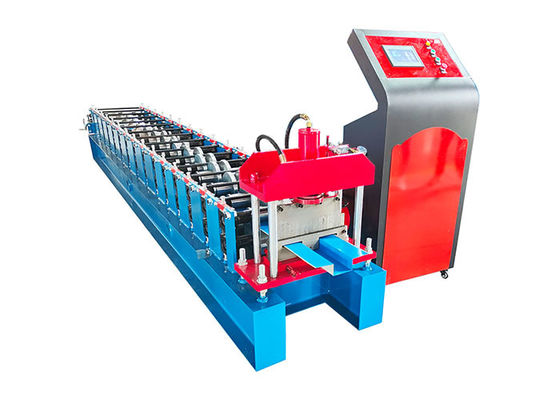

Color Metal Ridge Cap Roll Forming Machine Customized Design Easy Maintanace

1. Color Metal Ridge Cap Roll Forming Machine Customized Design Easy Maintanace

---- The ridge cap roll forming machine are mainly used to make the ridge capping.

---- Our roll forming machines require little maintanace, you can lubricate the ridge capping some times during daily production.

---- Operate easily, work automatically with PLC control system

---- Long time serive for completely ridge cap roll forming machine.

The components of the roll forming machine line includes:

| Hydraulic decoiler ( 5 Tons ) |

1 unit |

| Main Roll Forming Machine |

1 unit |

| Cutting Device |

1 unit |

| Electrical System with PLC Control |

1 unit |

| Hydraulic station |

2 unit |

| Auto stacker |

1 unit |

2. Color Metal Ridge Cap Roll Forming Machine Customized Design Easy Maintanace parameters

| 1 |

Coil Width |

1000mm |

| 2 |

Diameter of shaft |

70mm |

| 3 |

Forming Speed |

8-12meters/min |

| 4 |

Middle plate |

16mm |

| 5 |

Material of shaft |

45#steel with tempering |

| 6 |

forming thickness |

0.2mm-0.6mm |

| 7 |

material of rollers |

45#steel |

| 8 |

Cutting type |

hydraulic -cutting |

| 9 |

Main power |

4kw+3kw |

| 10 |

Main frame |

300H steel |

| 11 |

Control system |

PLC |

| 12 |

Brand of electrical parts |

Delta |

| 13 |

Manual decoiler |

5 tons |

| 14 |

Power |

3 Phase,380 Voltage,50Hz |

| 15 |

Dimensions(L*W*H) |

About 6.5*1.2*1.2M |

| 16 |

Weight |

about 3 tons |

3. Who we are and what we do

"The quality first, The prestige first" is the service aim of our company, we wish to customize the best machines for customers. So all stuff from SHITONG welcome anyone who are interested in our machines come to investigate and talk about cooperation.

SHITONG not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

4. Features of the roll forming machine production line

(1)Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

(2)1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 60m/min;

5). Very easy to install and operate the roll forming machine.

5. FAQ

5.1:.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

5.2:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

5.3: - Can you finish the machine during the delivery time?

A: We will finish the machine in time according to determined lead time.

5.4:- Can you provide some spare parts?

A:Yes, of course. The quick-wear parts are sent to you together with the machine.

6. Machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!