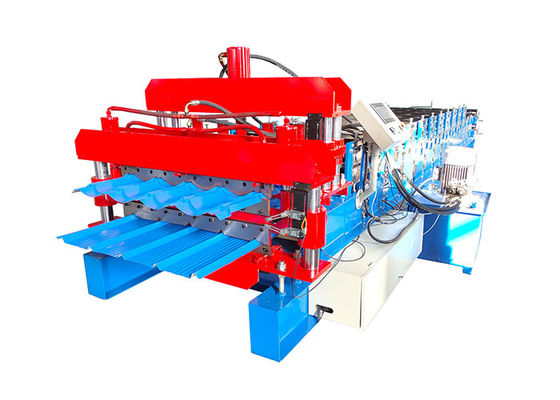

Two Roofing Tile Rolling Gruops Double Layer Roll Forming Machine High Efficiency

1.Two Roofing Tile Rolling Gruops Double Layer Roll Forming Machine High Efficiency

---- Double layer roll forming machine is combination of two roof sheet forming machine

----- There are various types of rib-type profiles depending on the customer requirement, the most common is the 6 rib type profile.

----- The rollers inside the machine will shape sheet metal to become a metal roofing sheet panel.

---- Double layer roll forming machine is fully automatic and is easy to operate with a friendly HMI panel.

2. Two Roofing Tile Rolling Gruops Double Layer Roll Forming Machine High Efficiency Parameters:

| Suitable to Process |

Color steel sheet ; Galvanized sheet ; Iron sheet; Aluminum sheet |

| Width of raw material |

914/1000/1200/1220/1250mm as usual;customized |

| Rollers |

customized |

| Dimensions |

About 7500*1550*1550mm |

| Power |

5.5+4kw |

| Thickness of sheet |

0.3-0.8mm as usual; customized |

| Material of cutting blade |

Cr12 |

| Diameter of the roller |

customized |

| Voltage |

380V, 50Hz, 3 phrases;customized |

| weight |

About 5T |

| Productivity |

10—-15m/min |

| Control system |

Automatically controlled by computer |

Standard Configuration:

| 5 tons Manual decoiler |

1 set |

| Main roll forming machine |

1 set |

| Hydraulic pump system |

1 set |

| PLC control system |

1 set |

| Receiving Table |

2 sets |

| Spare parts |

1 box |

Production Process:

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

3. Other business trems

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment.

Delivery Time

Within 35 days after receiving deposit.

Warranty

Two years, and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you. But you need to provide the cost of the engineer.

Packaging :

1. Tighten to container with steel wire rope and welded machine with container by angel iron

2. Main forming machine and un-coiler is naked (If you need we can also packed with water-proof plastic)

3. PLC contral system and motor pump are packed with water proof paper

Shipping :

1. One 20" container

2. One 40"container

.

4.FAQ

1. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine. It can produce 3 kinds of panels.

2. Do you have after sales support?

Yes, we are happy to give advice and we also have skilled technicians available across the world.We need your machines running in order to keep your business running.

3. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freell,but you need pay the express cost yourself.if after warranty period,we can through negotiationfor to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

7. Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing How to make machines much more automatic, accurate and high quality. We can make sure thatour machine could use more than 20 years without any problem. We can provide 2 years free qualityassurance.

8. How long the machine could be made?

Normally speaking, welded pipe making machine could be made without 45 working days. If you need machines in a hurry, we can make it for you less than a month.

5. Roofing Sheet And Glazed Tile Double Layer Roll Forming Machine For Custruction Material Pictures

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!