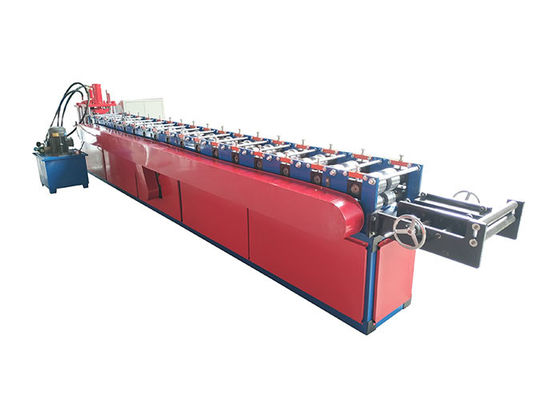

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Comapny advantage:

In Botou, we start the pressure roll forming machine export business from 2008.

As a manufacturer we are specialized in all kinds of roll forming machine, we are not machine supplier, we are a roll forming solution provider.

Provide best price,good quality and fast delivery.

5. FAQ

1. Q: How to visit our company:

A: Fly to Beijing Airport: By fast train From Beijing South station to Cangzhou west station

(1hour), then we can pick up you to factory(40min).

Fly to Shanghai Airport: By fast train From Shanghai Hongqiao station to Cangzhou west station(4.5 hours), then we can pick up you to factory(40min).

2. Q: What should I provide if I want to customized machine?

A: U need provide profile drawing, material, thickness, voltage and your special requirements.

3. Q: What is the Warranty?

A: Within 12 mounts, all technicals are ready to serve you at any time.

4. Q: What can you do if the machine broken?

A: Our machine's warranty period is 12 months, if the broken parts can't repair, we will send new parts replace the broken parts free, but you need pay the express cost if after warranty period. we can negotiate to solve the problem, and we supply the technical support for whole life of equipment.

5. Q: If need technician to workshop to debug and teach, how to do?

A: We sent technician to your country to fix the machine. Buyer should bear cost including: visa, round trip ticket and suitable accommodation, also buyer should pay the salary 100 USD/day.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!