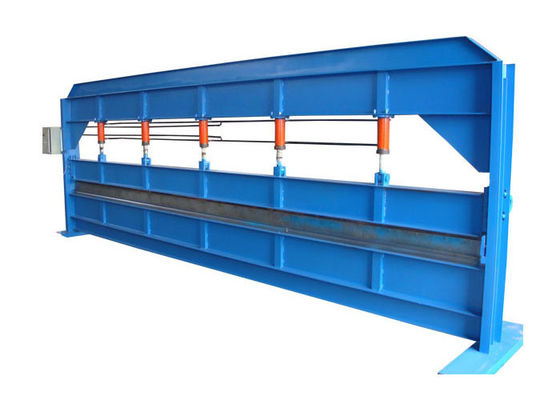

Tile making machine / roll forming machine / hydraulic bending machine

1. Usage And Introduction Of This Production Line

The complete bending machine includes manual decoiler, main body of roll forming machine, hydraulic cutting system, PLC control system and discharge table. The users can set order as per their requirement to produce the special pieces and length products. This machine line can work automatically by PLC control system. It is easy to operate and running stably.

2. The roll forming machine parameters

| Usage |

Ceiling, wall, roof and structure frame |

| Dimension |

6200*1200*1200mm |

| Weight |

2T or so |

| Feeding width |

6000mm |

| Forming thickness |

0.2-0.8mm |

| Large frame |

300mm I-Beam |

| Voltage |

380V 50HZ 3 phases or customized |

| Motor power |

3-5kw |

| Warranty |

1 year and we provide technical support for whole life, and overseas service |

| Maintain |

Easily :Timely adding oil |

| Payment terms |

30% in advance, the balance before delivery |

| Package |

Standard package |

| Delivery |

40 days after receiving deposit |

3. Who we are and what we do

SHITONG specializes in producing and designing each kind of roll forming machine such as roll forming machines for metal roofing tiles, wall panels. While consummating the old model, with the continuous efforts of our scientific researchers, our company developed one after another of Automatic Cutting and Punching C-type Steel Roll Forming Machine, Automatic Cutting and Punching Z-type roll forming machine, the production line of Glazed Tile Roll Forming Machine, Automatic Panel Machine, Guardrail Forming Machine, Shutter Door Forming Machine, which have the advanced technical level.

4. Features of the roll forming machine production line

1). To design and make the best roll forming machine, we took EUROPEAN quality standard;

2). Choose the best material and components, and adopting our 17+ years experience;

3). We achieves that the machine capacity is double of the competitors;

4). The machine working speed can be 60m/min;

5). Very easy to install and operate the roll forming machine.

5. Roll forming machine pictures:

6. FAQ

6.1: Do you have any other service?

A: We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

6.2:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

6.3:About the after service, if the machine has problem out of guarantee?

A: All the machines are one guaranteed, life maintenance. It means if you order our machine, you will be our customer for lifetime, you can ask us anytime about the machine issues.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!