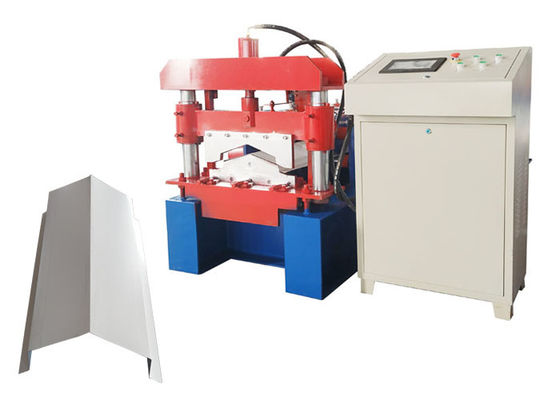

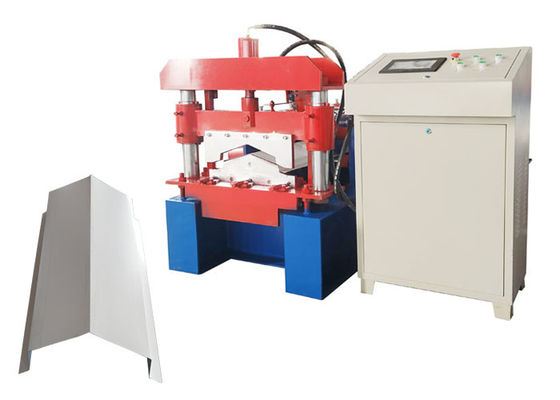

PPGI roof ridge tiles building materials machinery metal roof ridge cap roll forming machine

1. Usage And Introduction Of This Production Line

This machine line can work automatically by PLC control system. It is easy to operate and running stably.

-The machine is used for produce ridge cap tiles.We can manufacture sizes as customers request.

- The Roll Forming Machine used casting frame,this is kind of casting frame never cutting and welding,so this frame very strong and high precision.This kind of frame have long life working time.

The components of the roll forming machine line includes:

| Hydraulic decoiler ( 5 Tons ) |

1 unit |

| Main Roll Forming Machine |

1 unit |

| Cutting Device |

1 unit |

| Electrical System with PLC Control |

1 unit |

| Hydraulic station |

2 unit |

| Auto stacker |

1 unit |

2. The roll forming machine parameters

| No. |

Item |

Specification |

| 1 |

Steel coil |

Width |

Max 500mm

|

| Material |

Ppgi/gi/gl/Alu-zinc |

| Thickness |

0.21-0.29mm

0.3-0.6mm

0.3-0.8mm

|

| Hardness |

Normal hardness/G550/HRB90 |

| 2 |

Forming |

Frame |

300-450mm Height |

| Stations |

As design of drawing

Main: 16 stations

|

| Rollers |

High grade No 45# steel with

hard 0.05mm chromed

|

| Shaft |

High grade No 45# steel |

| Diameter of shaft |

As design of drawing

Main: 70mm

|

| Chain |

Main: 1inch |

| 3 |

Control |

PLC control |

China/Taiwan/Japan/Germany brand |

| Main motor |

Main: 5.5kw |

| Language |

English or as your request |

| 4 |

Cutting |

Cutter |

High grade Cr12 steel |

| Cutting system |

Hydraulic |

| Hydraulic pump |

Main: 3-7.5kw |

| Cutter frame |

Steel plate welding |

| 5 |

Decoiler |

Manual |

5 Tons |

| 6 |

Product |

Receiving table |

Manual |

3. Who we are and what we do

"The quality first, The prestige first" is the service aim of our company, we wish to customize the best machines for customers. So all stuff from SHITONG welcome anyone who are interested in our machines come to investigate and talk about cooperation.

SHITONG not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

4. Features of the roll forming machine production line

(1)Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building manufacturing, and have features such as nice appearance and durable.

(2)Our roll forming machine can be profile custom,and are lower cost,high efficiency,reliable working ,low energy consumption.we can do any type of equipment according to customer requirements.

(3) If the buyer need overseas debug, we can also send technician to your factory, the customer should undertake all related cost including the accommodation and round-trip ticket of technician: 100 USD/day . The buyer should make sure the safety of technician.

5. Roll forming machine pictures:

6. FAQ

6.1:.What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

6.2:How is this machine's service life?

A:In the normal maintenance,the service life at least 8 years.

6.3: What policy of your garentee?

A: Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!