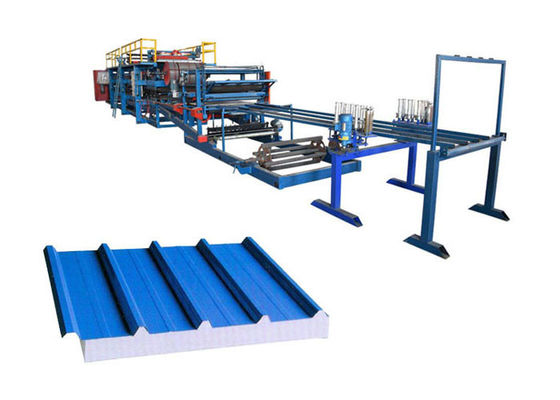

Sandwich panel trapezoidal roof tile making profile production line sheet roll forming machine

1. Instruction of the roll forming machine production line

Our roll forming machine can produce different kinds of steel panel tiles for roof and wall. The tiles is mainly used in temporary building site, steel constructure workshop,and other public building with fast building speed. It has advantage of pretty appearance, durable using and so on.

The metal sheet cold roll forming of us has characters of high spped ,high production, good performance, low labor and save cost. All the above characters are the best selections for producing the metal sheet cold roll form products.

The components that each set machine includes:

| COMPONENT FOR roll forming machine |

| Name |

Quantity |

Units |

| Decoiler |

1 |

Set |

| Main Machine |

Feeding device |

1 |

Set |

| Roll forming system |

1 |

Set |

| Cut Equipment |

1 |

Set |

| Hydraulic system |

1 |

Set |

|

Electriccontrol system

|

1

|

Set |

| Supporter/Automatic Stacker |

1 |

Set |

2. The roll forming machine parameters

| No. |

Item |

Specification |

| 1 |

Can Formed Material |

PPGI,GI,AI |

| 2 |

Equipment operation |

Automatic |

| 3 |

Voltage |

380V 50Hz 3Phase or as your requirement |

| 4 |

Thickness of sheet (mm) |

0.4-0.7mm |

| 5 |

Material width(mm) |

As your requirement |

| 6 |

Cover Width of the sheet after formed |

as your drawing |

| 7 |

The size of the roll forming machine |

19500mmx1950mmx2200mm |

| 8 |

Speed |

5-8m/min |

| 9 |

Diameter of shaft |

70mm |

| 10 |

Weight of the Machine |

22000-23000KGS |

| 11 |

Material of rollers |

C45 steel quenched and chromed |

| 12 |

Motor brand |

Siemens or Guomao |

| 13 |

PLC |

Siemens or Delta or Mitsubushi |

| 14 |

Total power (kw) |

32kw |

3. Who we are and what we do

We manufacture wide range products of metal sheet cold roll forming machine as follows: color steel roll forming machine, glazed tile roll forming machine, C/Z/U purlin machine for light steel structure building, floor deck machine, sandwich panel production line, fast guardrail forming machine, ridge cap forming machine and other automatic cold bending roll forming equipment. Our export team will listen to your request; the designed team will show you the best proposal according to your request, and we also have experts skilled workers offer precision work. Satisfactory solutions were provided to customers and established a long-term strategic partnership.

4. Features of the roll forming machine production line

a) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

b) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

d) It is very easy to install the equipment and suitable for producing in the factory.

e) Low noise with high efficiency

5. Roll forming machine pictures:

6. FAQ

Q1: If our country's voltage is different from yours, how to solve that?

- The usual voltage is 380v,220v,415v. If yours are not one of them, we will design the electric motor to suit your voltage.

Q2: How can we be assured that you will deliver us quality machine with spare parts?

-1. Customers to send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer`s factory for the installation of the machine.

Q3, What policy of your garentee?

- Within the One-YEARS period, we could supply you the replacement parts free of charge

for any damaged parts caused by quality problems after two years,you need to buy by factory cost.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!