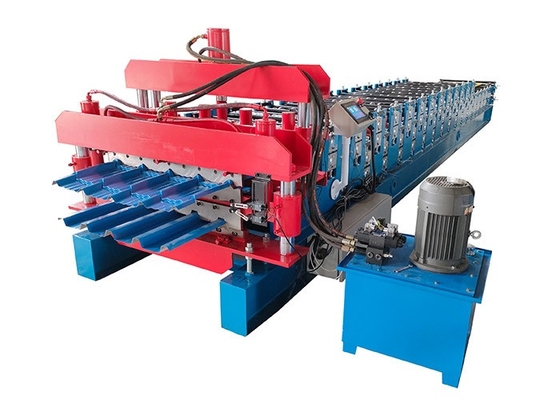

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Our service

Pre-sale Service

A1. Send you invitation letter, If you wanna visit our factory and check the machines.

A2. Good Quality Manufacturer competitive price Quick Response Reliable Service for you.

Selling Service

B1. Short delivery time after deposit 30-40 days.

B2. Email you the production schedule and make prompt delivery for you.

B3. We will count the cheapest shipping cost and fastest forwarder for you and send documents promptly.

B4. Always be here for your service 12 hours per day.

After-sale Service

C1. We welcome all feedback about our products and prices and services from our customers.

C2. Any questions, please contact with us freely by E-mail or Telephone.

5. FAQ (about our roll forming machine)

1) Which type payment termsyou accpect ?

Yes,we accpect T/T from almost all countries.

2) What's your payment terms and delivery time?

30% as the deposit by T/T in advance, 70% as the balance payment by T/T after your inspectthe machine well and before delivery. Of course your payment terms are acceptable.After we get down payment, we will arrange production. About 30-45 days for delivery.

3) Do you have after -sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across theworld.

4) Do you sell only standard machines?

No, most of our machines are built according to customers specifications, using top brand com-ponents.

5) What will you do if the machine is broken?

We provide 18 months free warranty and free technical support for the whole life of anymachine.If the broken parts can't repair, we can send the new parts replace the broken parts freely, but youneed pay the express cost by yourself. If it is beyond the warranty period, we can negotiate tosolve the problem, and we supply the technical support for the whole life of the equipment.

6.Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!