Efficient metal double layer aluminium steel roofing sheet roll forming making machine for European market

1. Usage And Introduction Of This Production Line

The complete double layer roll forming machine line , includes manual decoiler, main body of roll forming machine, hydraulic cutting system, PLC control system and discharge table. The users can set order as per their requirement to produce the special pieces and length products. This machine line can work automatically by PLC control system. It is easy to operate and running stably.

| Hydraulic decoiler ( 5 Tons ) |

1 unit |

| Main Roll Forming Machine |

1 unit |

| Cutting Device |

1 unit |

| Electrical System with PLC Control |

1 unit |

| Hydraulic station |

2 unit |

| Auto stacker |

1 unit |

2. The roll forming machine parameters

| 1. |

Power

requirement

|

Type |

220v/380v/3ph/50hz |

| |

|

Main Motor power |

5.5kw |

| |

|

Cutter power |

4kw |

| 2. |

Forming speed(m/min) |

8-15 |

Not include the time of cutting |

| 3. |

Forming stations |

16 |

Depend on actual design |

| 4. |

Thickness of structure |

14mm |

|

| 5. |

Forming shaft diameter(mm) |

70 |

|

| 6. |

Chains |

1 inch |

|

| 7. |

Sleeve |

5mm thickness thick wall pipe instead of galvanized pipe |

|

| 8. |

Type of cutting |

Roll formed and length-set cutting |

|

| 9. |

Control system |

PLC Panasonic Inverter Schneider |

|

| 10. |

Install dimension(depend on the final design) |

7.5m×1.5m×1.2m |

Without panel length |

| 11. |

Total weight (Approx) |

4T |

Depend on final design |

| 12. |

Screen |

Text screen /touch screen |

|

3. Who we are and what we do

SHITONG specializes in producing and designing each kind of roll forming machine such as roll forming machines for metal roofing tiles, wall panels. While consummating the old model, with the continuous efforts of our scientific researchers, our company developed one after another of Automatic Cutting and Punching C-type Steel Roll Forming Machine, Automatic Cutting and Punching Z-type roll forming machine, the production line of Glazed Tile Roll Forming Machine, Automatic Panel Machine, Guardrail Forming Machine, Shutter Door Forming Machine, which have the advanced technical level.

4. After-sales service

(1) Once you paid the deposit, we will start the production as soon as possible. When the machine is finished, you can come to check the machine, we will arrange your accommodation and relative schedule. If you don't come, we can test the machine and send you test video. It's no problem.

(2) Our machines have one year guarantee, within one year, if the machine parts has some problem, we will be in charge of the repairing or replace. Also we will deliver the customer some spare parts together with the machine when loading the machine.

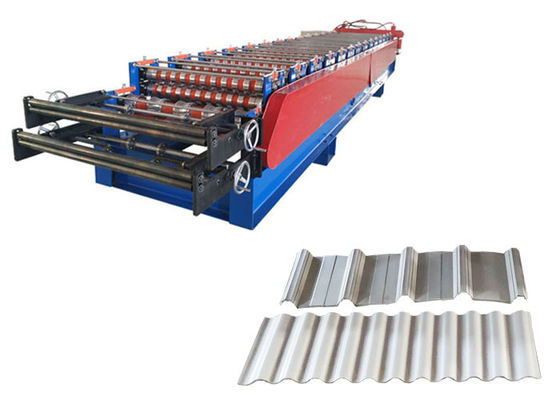

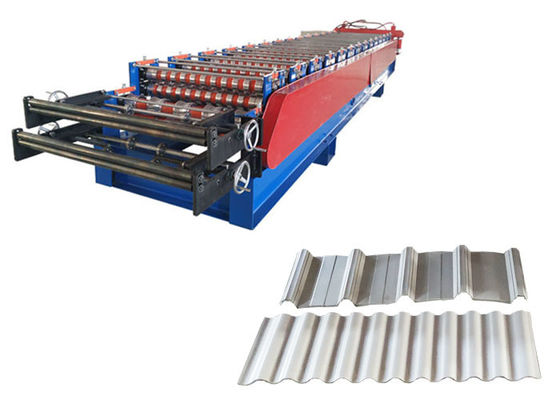

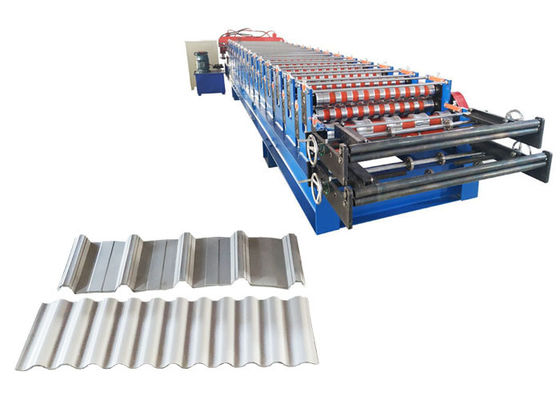

5. Roll forming machine pictures:

6. FAQ

1:- What service can you provide before order?

- About the pre-sale service. We provide you answers of all your questions on our machines, such as technical parameter, price, payment terms, ect. If you wanna visit our factory and check the machines, we also can send you invitation letter and give you our warmest welcome.

2:- Do you have any other service?

- We can manufacture, design, installation and debug various roll forming machines including standard and customized machines.

It is free to assemble machine and train your works, but the buyer should pay for the round-trip airplane ticket, and arrange accommodation during that time.

3:- Can you provide some spare parts?

- Yes, of course. The quick-wear parts are sent to you together with the machine.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!