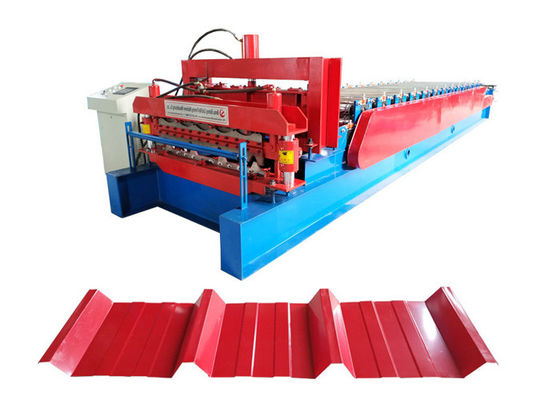

Double deck roll forming machine roll formers metal roofing corrugated steel sheet wall panel tile making machine

1. Instruction of the roll forming machine production line

- Strong Power Light Keel Steel Roll Forming Machine used for produce furring channel and drywall profile.We can manufacture sizes as customers request.

- Strong Power Light Keel Steel Roll Forming Machine used casting frame,this is kind of casting frame never cutting and welding,so this frame very strong and high precision.This kind of frame have long life working time.

- Strong Power Light Keel Steel Roll Forming Machine,we used double bearings,so we make sure machine working low noise and more stable working.

2. The roll forming machine parameters

| No. |

Item |

Specification |

| 1 |

Can Formed Material |

PPGI,GI,AI |

| 2 |

Equipment operation |

Automatic |

| 3 |

Voltage |

380V 60Hz 3Phase or as your requirement |

| 4 |

Thickness of sheet (mm) |

0.6-0.8mm |

| 5 |

Material width(mm) |

As your requirement |

| 6 |

Cover Width of the sheet after formed |

as your drawing |

| 7 |

The size of the roll forming machine |

5000mmx1200mmx1400mm |

| 8 |

Speed |

12-15m/min |

| 9 |

Diameter of shaft |

40mm |

| 10 |

Weight of the Machine |

3000-3500KGS |

| 11 |

Material of rollers |

C45 steel quenched and chromed |

| 12 |

Motor brand |

Siemens or Guomao |

| 13 |

PLC |

Siemens or Delta or Mitsubushi |

| 14 |

Total power (kw) |

8kw |

| 15 |

Power of hydraulic system |

4kw |

| 16 |

Power of main molding core |

4kw |

3. Who we are and what we do

SHITONG specializes in producing and designing each kind of roll forming machine such as roll forming machines for metal roofing tiles, wall panels. While consummating the old model, with the continuous efforts of our scientific researchers, our company developed one after another of Automatic Cutting and Punching C-type Steel Roll Forming Machine, Automatic Cutting and Punching Z-type roll forming machine, the production line of Glazed Tile Roll Forming Machine, Automatic Panel Machine, Guardrail Forming Machine, Shutter Door Forming Machine, which have the advanced technical level.

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Features of the roll forming machine production line

a) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

b) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

c) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming .

d) It is very easy to install the equipment and suitable for producing in the factory.

e) Low noise with high efficiency

5. Roll forming machine pictures:

6. FAQ

6.1:Can you be responsible for transport?

A:Yes,please tell me the destination port or address.we have rich experience in transport.

6.2:Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

6.3:How many workers operate this machine to manufacture?

A:Only 1-2 worker.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!