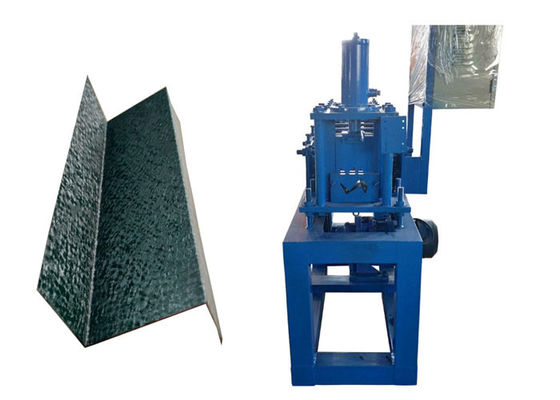

automatic ceiling angle iron light steel keel roll forming machine

1. Company information

BOTOU SHITONG COLD ROLL FORMING MACHINERY MANUFACTURING CO.,LTD. starts roll forming machine since 2001.

We know well the requirements for the customers from different countries and have an outstanding export teams who will take care of your requests. Our experts and skilled workers complete the work with great precision.

We provide an extensive line of products, including roof and wall panel machine, tile roof machine, purlin forming machine, shutter door machine, floor decking machine and other associated equipment.

Our products have been sold worldwide over 90 countries including America, the UK, Australia, India, Sri Lanka South Africa, Tanzania, Nigeria etc.

We have first-class mechanical processing equipment, physics laboratory equipment, nondestructive testing equipment and chemical analysis room. The most advanced full digital computer test method is used to produce quality grid and light steel structures and equipment.Our various equipment products have been exported to Canada, South Korea, Suriname, Sri Lanka, Mongolia and other countries.

Dingtai owns a perfect customer service service team, to provide full support to your customer service, help you get the most satisfactory equipment, ensure that you promptly solve all the problems encountered in the process of equipment usage, and our service.

Your interests and concerns are always our priority which inspires us to improve efficiency, reduce costs, enhance competitiveness to service you.

Listen carefully to your requirements and requirements, design and manufacture fully in accordance with your requirements and needs, and help you get the most reasonable equipment.

We sincerely hope to cooperate with you, mutual benefit and win-win situation.

2. Technical parameters:

| Raw material |

| material spec |

sheet, galvanized steel sheet, aluminum sheet |

| thickness of coil sheet |

0.5-3mm |

| Machine details |

| roller material |

High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| shaft material |

High grade NO. 45 carbon wrought steel |

| cutting blade |

Cr12 mould steel with quenched treatment |

| diameter of shaft |

70mm |

| forming steps |

11 rows |

| productivity |

25-30m/min |

| hydraulic station power |

22 KW |

| hydraulic pressure |

10-12MPa |

| controlling system |

famous PLC computer control |

| material of cutting table |

Cr 12 mould steel with quenched treatment |

| appearance size |

7500mm*1150mm*1510mm |

| hydraulic oil |

40# hydraulic oil |

| Electric tension |

380V 50 Hz 3 Phase or as your requirements |

- Electronic control system

|

|

Description

|

- The machine used well-known brand PLC control technology. To realize the automatic machine

- The system to provide friendly man-machine interface, It can be set batch, workpiece length and number, etc.

- Encoder count, count and length with function.

- PLC touch screen adopt domestic famous brands.

|

3. Machine picture

4. Installation and training:

A. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also trainyour workers/technician face to face.

B. Without visiting, we will send you user manual and video to teach you to install and operate.

C. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.

5. FAQ

1. what is your guarantee period?

Guaranteed against malfunctions due to manufacturing defects for 12 months from the date of loading.

2. Do you provide training for my workers?

The machine has been installed and tested well before shipping. It is easy to operate.

Normally speaking, our customer follows the instruction book and can operate the machine well.?

You can also come to our factory to check the machine and learn how to operate before shipping. It only needs 2 hours and you can operate well.

3. I do not know about the machine and do not know how to install it. Can you install the machine in my factory?

If you need us to send engineers to your factory, you will pay for the travel expense such as visa, round tickets, hotel, food Salary of 80 USD per day per person (from departure from our factory, until we are back to our factory). You also need to take care of his safety.

4. What is included in the machine?

The process for work: decoiler→feeding→roll forming→measuring length→cutting to length→product to stand

The whole line includes a manual decoiler, roll forming machine and product stand. when you get the machine in your factory, you just need to do following 3 things, and then you can start working.

a. Put the machine on the flat level ground.

b. Inject gear oil and hydraulic oil.

c. Connect 3 phase electric wire.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!