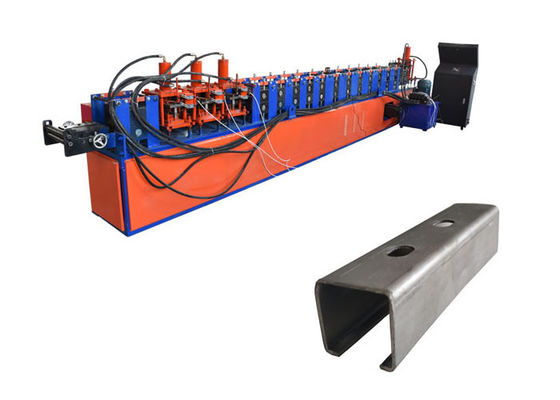

Hand touch screen light steel keel roll forming machine for C stud channel manufacture

1. Hand touch screen light steel keel roll forming machine for C stud channel manufacture

---- We used welded steel frame structure for this machine to make sure machine have a good quality, meanwhile, we use AC frequency conversion motor reducer drive, chain transmission, roller surfaces polishing, hard plating, heat treatment and chrome coating... to prove machine in good situation.

---- The cutter is drived by a hydraulic system, this system have a giear pump, need fill hydraulic oil in to the oil tank, then the pump can drive the hydrualic cylinder to work.

---- Shearing Mechanism adopts the hydraulic drive and automatic location to decide the dimension and cut the target products

---- A friendly interface of the hand touch screen, easy to learn how to operate the machine control system.

2. Hand touch screen light steel keel roll forming machine for C stud channel manufacture parameters

| Material |

Colored steel sheet, galvanized steel sheet, aluminum sheet |

| Thickness of coil sheet |

0.5-1 mm |

| Efficiency width |

25/30mm |

| Machine details |

| Roller material |

High grade NO. 45 forged steel with 0.05mm hard chrome plating |

| Shaft material |

High grade NO. 45 carbon wrought steel |

| Cutting blade |

Cr12 mould steel with quenched treatment |

| Diameter of shaft |

70mm or as your requirement |

| Main frame |

300 H steel |

| Forming steps |

16 stations |

| Productivity |

30-35m/min |

| Hydraulic station power |

5.5 KW |

| Hydraulic pressure |

10-12MPa |

| Appearance size |

7700mm*1500mm*1500mm |

| Hydraulic oil |

40# hydraulic oil |

| Electric tension |

380V 50 Hz 3 Phase or as your requirement |

| Cut Mode |

Hydraulic forming after cutting off |

| Cutter materia |

Cr12 Heat Treatment |

| Electronic control system |

PLC, Touch Screen, Encoding counter |

| Color |

Blue, green or yellow or as your requirement |

| Rolling material |

45# steel,roller surfaces polishing, hard plating |

| Machine Components |

| No. |

Name |

QTY |

| 1 |

Manual uncoiler |

1 set |

| 2 |

Feeding and leveling device |

1 set |

| 3 |

Roll forming system |

1 set |

| 4 |

Hydraulic punching and cutting |

1 set |

| 5 |

Product support frame |

1 set |

| 6 |

PLC Control System |

1 set |

3. roll forming machine company profiles

Botou Shitong Cold Roll Forming Machinery Manufacturing Co.,Ltd. is a professional manufacturer and exporter that are concerned with the design, development and manufactur of cold roll forming machines. We have high quality professional teams, skillful talents, strong technical force, strong and independent research and development capabilities, advanced production equipment and a perfect after-sales service system.

The company is specialized in manufacturing Color steel forming machinery, C and Z purling machine, Glazed tile forming machine, steel structural floor panel roll forming machine, sandwich panel roll forming machine, highway guardrail forming machine, downspout forming machine, car panel roll forming machine, roll shutter door roll forming machine, sheet slitting equipment, and other equipment accessories.

4. Our advantage

1. We are a factory with nearly 20 years experiences on Roll Forming Machines;

2. We have our own research and development team with strong ability to solve all kinds of problems;

3. We have stable raw material suppliers to ensure the best quality and on time supplying with low cost;

4. We have more than 20 technicians that can go abroad for the after-sale service;

5. We have more than 100 kinds and models products for your choice, you can find the most kind of roll forming machines from us;

6. We have Laser Cutting Machine, CNC Machining Center, Polishing Line, Painting Line, etc. advanced production equipments to ensure the quality of each part and the best appearance of our machines;

7. Our machines have reached the International Inspection Standards;

8. We have got the ISO9001:2008 Certificate and CE Certificate;

9. We are always waiting to serve you 7 days a week and 24 hours a day.

5. FAQ

1. How to play order :

Inquiry---confirm the profile drawings and price---confirm the PI---arrange the deposit or L/C---then OK

2. Do you have after -sales support?

Yes, we are happy to provide advice and we also have skilled technicians available across theworld.

3. Do you sell only standard machines?

No, most of our machines are built according to customers specifications, using top brand com-ponents.

4. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't repair,we can send the new parts replace the broken parts freely,but you need pay the express cost yourself.if after warranty period,we can through negotiation for to solve the problems,and we supply the technical support for the whole life of the equipment.

5. Can you be responsible for transport?

Yes,please tell me the destination port or address.we have rich experience in transport.

6. You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for

6. Roll forming machine pictures:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!