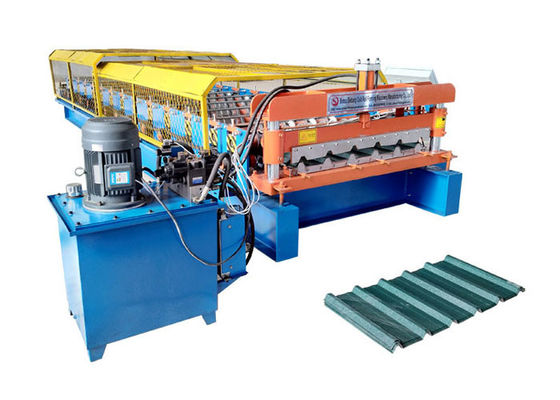

roofing panel trapezoidal shape Sheet Metal Roll Forming Machines with safe cover

| Voltage |

380V 50HZ 3Phase |

| Appearance size (About) |

6700mm*1500mm*1500mm |

| Weight(About) |

3.5 tons |

| Length measurement |

Encoder |

| Control mode |

Delta PLC |

| Operating mode |

Button + Delta Touch screen |

| Material |

GI, PPGI, PPGL |

| Width |

1220mm |

| Thickness |

0.2-0.8mm |

| Yield strength |

Q235 |

| No |

|

Technical Specification |

| 1 |

Manual Uncoiler

|

Usage: It is used to support the steel coil and uncoil it in a turntable way. The steel coil is uncoiled by hand. Loading capacity:1T

Inner diameter: 500-508mm

|

| 2 |

Main Roll Forming Machine

|

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped. |

| 3 |

Shearing Mechanism

|

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

|

| 4 |

Hydraulic System

|

Power:4kw,Hydraulic oil: 40#

Hydraulic oil into the hydraulic oil tank, the pump drives the cutter machine to begin the cutting job.

|

| 5 |

Computer Control Cabinet

|

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The PLC system is easy to operate and use |

| 6 |

Spare parts

|

One box

Counter Wheel (1 PCS)

Bearing (2 PCS)

Hydraulic Oil Pipe (2 PCS)

Position Switch (2 PCS)

|

We have good quality and competitive prices, we produce our machines in European standard and quality level.

We exported our products more than 30 countries until today, included Roll Forming Machine Line with Punching, Plaster Board Rollform Machine Line, Drywall Board Roll Forming Production Line, Roll Forming Machine, Metal Drywall Board Profile Roll Forming Machine Line, Plaster Board Roll Forming Machine, Plaster Board Roll Forming Machines, Metal Drywall Plaster Board Profile Machine, Plaster Board Drywall Profile Machine, Steel Plaster Board Profile Machine, Roll Forming Sheet Metal Machine, Roll Form Machine, Sheet Metal Forming Machine, Metal Forming Machine, Metal Forming Machinery, Roll Forming Machine, Roll Forming Machines, Roll Forming Machinery, Roll Forming Machineries, Rollform Machine, Rollform Machines, Rollform Machinery, Rollform Machineries, Drywall Rollform Machine, Plaster Board Rollform Machines, Plaster Board Rollform Machineries, Plaster Panel Rollform Machinery, Drywall Panel Rollforming Machine, Construction Rollforming Machines, Construction Roll Forming Machinery, Steel Rollform Machine, Metal Rollform Machine, Sheet Rollform Machine, Steel Roll Forming Machine, Metal Roll Forming Machine, Sheet Roll Forming Machine, Construction Roll Forming Machine, Plaster Drywall Roll Form Machine, Plaster Drywall Roll Forming Machine, Drywall Plaster Roll Form Machine, Plaster Drywall Roll Forming Machinery, Plaster Drywall Roll Form Machinery, Plaster Drywall Roll Form Machinery, Plaster Drywall Roll Forming Machinery, Roll forming Machine Line with Punching, Roll Forming Machinery Line with Punching, Roll Forming Machine with Punching, Roll Forming Machinery with Punching, Rollform Machine with Punching, Rollform Machinery with Punching, Roll Form Machine with Punching, Roll Form Machinery with Punching and Metal Rollforming Machineries.

For more information.

You can visit our web page and you can see more options

Best regards

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!